Wholesale Transition Fabrication by Wear Plates

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Wholesale Transition Fabrication by Wear Plates, Are you still seeking for a high quality product that is in accordance together with your good corporation image while expanding your product or service range? Try out our high-quality solutions. Your choice will prove for being intelligent!

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for China Wear Resistant Plates and Chromium Carbide Overlay, We have been persisting in the business essence “Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying goods and service. ” Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

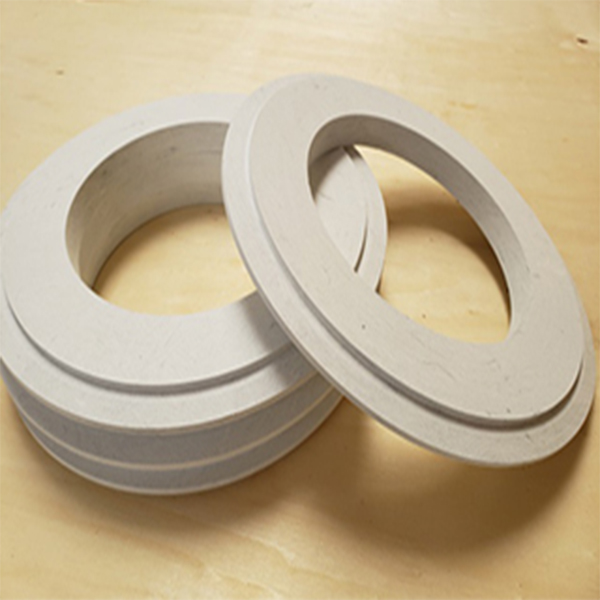

Product advantages:

1. Good non-wetting property, smooth glaze surface, high geometric processing precision and low maintenance cost.

2. There is no delamination and peeling phenomenon, which can effectively reduce the pollution of molten aluminum and achieve pollution-free refined aluminum casting.

3. Erosion resistance, good thermal shock resistance, improved corrosion resistance to molten metal.

4. It is better to use with boron nitride (BN) paint, and the life is normal 450-800 casting times, so as to save energy and reduce consumption.

Instructions for use of casting accessories:

1. Select the hot top casting equipment platform installation accessories of corresponding specifications.

2. Install the shunt plate, sleeve, adapter plate, shunt tank, and graphite ring on the upper side of the platform, and install the sleeve, adapter plate, and graphite ring on the inner side of the crystallizer to ensure cleanliness, no damage, and no gaps. It is best to use ceramic fiber paper or ceramic fiber blanket to seal the bottom and the bottom, which is helpful for heat preservation.

3. After the integral hot top casting platform is installed, uniformly preheat the installed and standardized equipment platform to 260-350°C. Electric or gas baking can be used. No open flames should contact the product inner lining, otherwise cracks will appearand the damage shall be borne by the user, so that it can remove the adsorbed crystal water and use it safely and efficiently.Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Wholesale Transition Fabrication by Wear Plates, Are you still seeking for a high quality product that is in accordance together with your good corporation image while expanding your product or service range? Try out our high-quality solutions. Your choice will prove for being intelligent!

Wholesale China Wear Resistant Plates and Chromium Carbide Overlay, We have been persisting in the business essence “Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying goods and service. ” Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.