Wholesale Price China Carolina Metal Systems - Resistance Flexible Graphite Ring Rroduct for Aluminium billet casting – ZheLu

Wholesale Price China Carolina Metal Systems - Resistance Flexible Graphite Ring Rroduct for Aluminium billet casting – ZheLu Detail:

1.Select the hot-top casting equipment platform installation accessories of the corresponding specifications;

2.install the distribution plate, sleeve, adapter plate, distribution groove, and high-purity graphite ring on the upper side of the platform, and install the sleeve, adapter plate, and graphite ring on the mold.

On the inside, ensure clean, no damage and no gaps. It is best to use ceramic fiber paper or ceramic fiber blanket to seal the sides and bottom, which is helpful for thermal insulation.

3.After the overall hot top casting platform is installed, evenly preheat the installed standard equipment platform to 260-350 ℃, by electricity or gas. No open flame should contact the lining body of the product, Otherwise, the crack damage that occurs shall be borne by the user.

4.remove adsorbed crystal water, Make it safe and efficient use

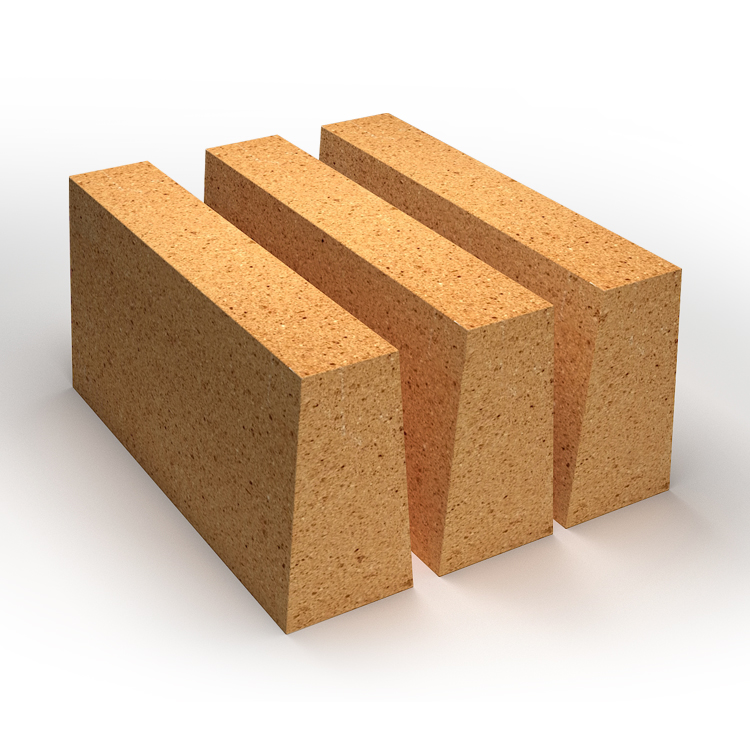

Product detail pictures:

Related Product Guide:

The company has set branches and warehouses in Hanoi and Ho Chi Minh, Vietnam.Yearly we exports there more than 6,000 tons of casting and extrusion consumables ,as well as dozens of casting and extrusion production lines. In the future, we will set up our branch offices in more countries, through face-to-face communication with customers, we will provide door-to-door one-stop service to our customers to solve all the problems. Wholesale Price China Carolina Metal Systems - Resistance Flexible Graphite Ring Rroduct for Aluminium billet casting – ZheLu , The product will supply to all over the world, such as: Hanover, San Francisco, Afghanistan, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.