Welcome to our websites!

Well-designed Molten Boron - Refractory Alumina Porous Ceramic Foam Filter Plate For Molten Aluminium – ZheLu

Well-designed Molten Boron - Refractory Alumina Porous Ceramic Foam Filter Plate For Molten Aluminium – ZheLu Detail:

Product detail pictures:

Related Product Guide:

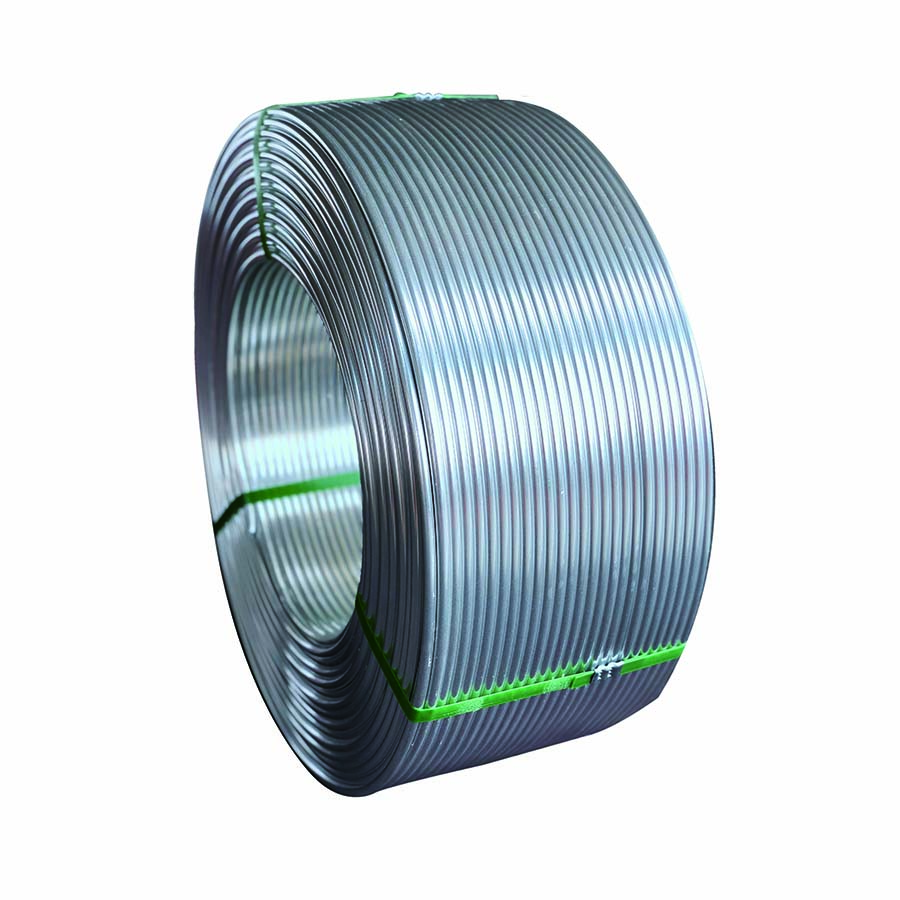

Our complete line solutions include: aluminum alloy ingot/Billet production line and aluminum extrusion production line. Well-designed Molten Boron - Refractory Alumina Porous Ceramic Foam Filter Plate For Molten Aluminium – ZheLu , The product will supply to all over the world, such as: Romania, Costa Rica, Israel, Aluminum is the metal of the future, it is not only environmentally friendly, light weight, natural corrosion resistance, high strength, but also good thermal and electrical conductivity.Characteristics of aluminum profiles: durable. Aluminum's corrosion resistance, corrosion resistance and weathering resistance are among its most significant advantages. Aluminum does not require additional treatment to rust naturally and resist corrosion. This is due to the presence of a thin, naturally occurring protective film of alumina on its surface. Through anodizing, its corrosion resistance becomes stronger.

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.