Welcome to our websites!

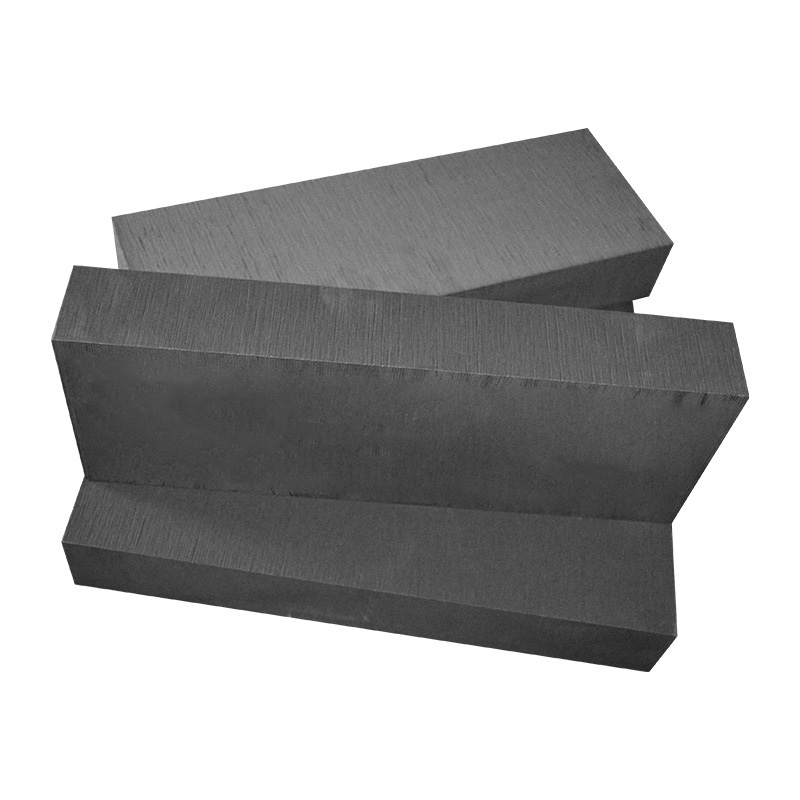

Well-designed Mandrel In Extrusion - High density melting aluminium clay graphite crucible for induction furnace – ZheLu

Well-designed Mandrel In Extrusion - High density melting aluminium clay graphite crucible for induction furnace – ZheLu Detail:

Product detail pictures:

Related Product Guide:

Foshan Zhelu not only provides sales services, but also helps companies in aluminum industry to solve all the problems. Welcome enquiries. Well-designed Mandrel In Extrusion - High density melting aluminium clay graphite crucible for induction furnace – ZheLu , The product will supply to all over the world, such as: Hungary, Hongkong, Cyprus, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!