Vacuum Varying Pressure Nitriding Furnacea To Nitriding Extrusion Die

1. Fast penetration

Holding time: 8-10 hours, high permeability layer: 0.14-0.18mm, white layer: 0.006-0.01mm

2. High surface hardness

Surface hardness can reach HV1000~1200

3. Good uniformity of furnace temperature

Special sealed circulating fan for nitriding furnace, furnace temperature uniformity ±5℃

4. Wide adaptability and uniform penetration layer

5. High degree of automation and simple operation

6. High vacuum sealed furnace tank, high efficiency and environmental protection

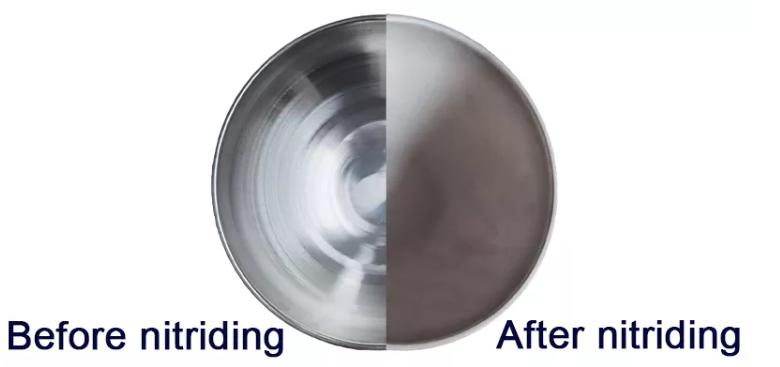

After nitriding, a white nitrided layer is formed on the surface of the workpiece, which makes the workpiece obtain higher hardness, higher wear resistance, higher corrosion resistance and longer service life.

Welded by A3 high-quality carbon steel and made into a single layer shell, thickness is 6mm. Have sufficient strength and rigidity, can bear the weight of the furnace and workpieces, and keep geometric shapes Non-deformation.

Use of lightweight refractory brick and aluminum silicate fiber cotton, composed of thermal insulation fireproof layer and insulating layer, heat insulation refractory layer using high strength lightweight and high alumina refractory bricks, are according to the laying process standard execution, has good heat insulation performance, service life in more than 5 years.

Adopt for high quality 321 heat resistant stainless steel plate, thickness is 8 mm . Has long service life under rated temperature. The furnace pot rests on the bottom to increase the atmosphere inside of the furnace and increase the pot service life.