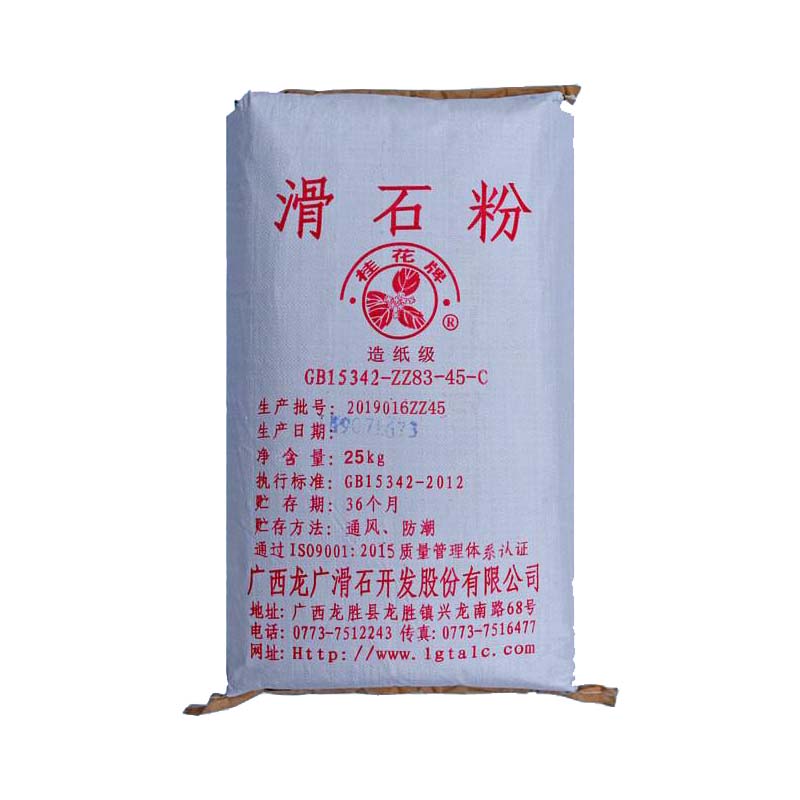

Different industrial grades talcum powder ingredients for ceramic use

The talc ore is sent to a hammer mill for coarse crushing, and the pulverized product is sent to a vertical dryer for drying through a bucket elevator and a vibrating feeder. After drying, the product is pulverized by a hammer mill. The medium crushed product enters the pulverizer from the feed hopper for pulverization, and the pulverized material is transported to the jet pulverizer for ultra-fine pulverization to obtain a product with a fineness of 500-5000 mesh.

This product is a white or off-white, non-gritty fine powder with a slippery feel. This product is insoluble in water, dilute hydrochloric acid or 8.5% sodium hydroxide solution.

It is used as a filler for plastics, improves processing performance, and improves the mechanical strength, heat resistance and tensile strength of products. When used in plastic films, it can increase the transmittance of plastic films to scattered light. Adding talcum powder to paints and coatings can improve dispersion, fluidity and gloss. Alkali corrosion performance, and good water resistance, pollution resistance, strong aging resistance, wear resistance, steam resistance and chemical stability, and has strong flame retardant properties, in addition to replace some titanium dioxide. Talc is also used as a textile filler and whitening agent; a carrier and additive for medicine and food.