Product Detail

Product Tags

Related Video

Feedback (2)

The global aluminum production market is looking forward to us. In line with the goal of building a grand brand of the enterprise, we adhere to steady operation and long-term development, and at the same time rely on strong human resources, rigorous production management and business philosophy, through the accumulation of our own experience and the unremitting pursuit and improvement of the future, and constantly carry out self-innovation, scientific and technological innovation, management and business philosophy innovation, in line with the trend of today's aluminum product development, to provide you with high-quality, low-priced, more fashionable products. Welcome friends from all walks of life to visit, guide and negotiate business. Refractory Plates, Sealing Agent, Copper Extruding, Aluminum casting process: The recycled aluminum scrap is to be heated and melted in an aluminum melting furnace,add with pure aluminum ingot, with refining flux and dross flux, the impurities will be removed, Then silicon and magnesium will be put into molten aluminum ,After flowing into launder and filter box,the molten aluminum finally reach the ingot casting line, with stacking robot, aluminum ingot will be stacked and packaging. While aluminium billet is another casting equipment, molten aluminum flows into Hot top casting plate, after cooling and Lifting and lowering of pallets, the billet will be made under the plate, then aluminum billet is hoisted out by the crane and enters the homogenization furnace, finally cut by saw.

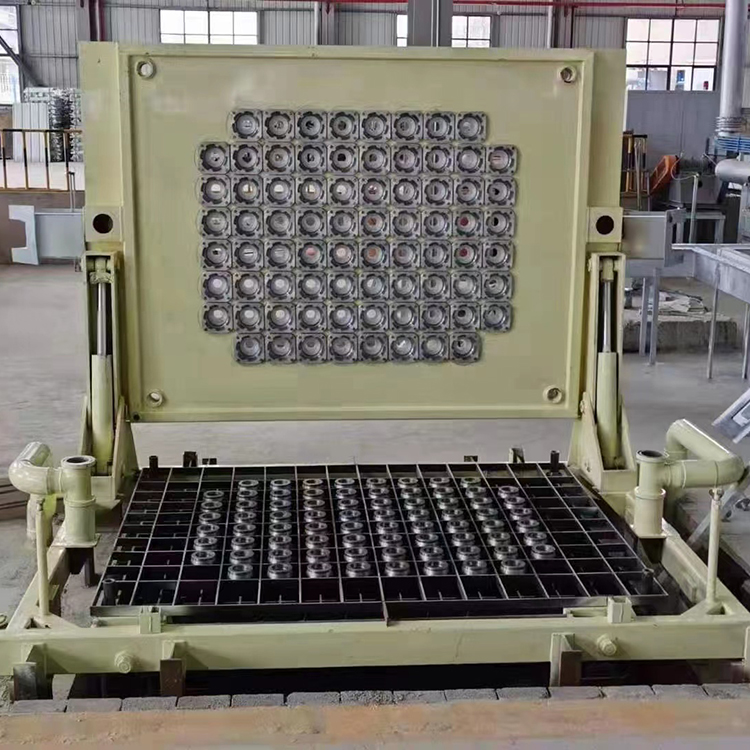

Top Suppliers Electric Furnace Casting - Refractory Alumina Porous Ceramic Foam Filter Plate For Molten Aluminium – ZheLu Detail:

Product detail pictures:

Related Product Guide:

Our products are mainly used in the smelting process of the aluminum casting industry and the extrusion process of aluminum profiles. Top Suppliers Electric Furnace Casting - Refractory Alumina Porous Ceramic Foam Filter Plate For Molten Aluminium – ZheLu , The product will supply to all over the world, such as: Rio de Janeiro, Liberia, Frankfurt, Foshan Zhelu has successfully developed 6 series aluminum alloy profile products with high strength and high corrosion resistance, which can be used in ships and other fields.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

By Wendy from Tunisia - 2018.02.12 14:52

By Wendy from Tunisia - 2018.02.12 14:52

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

By Antonio from Holland - 2018.09.16 11:31

By Antonio from Holland - 2018.09.16 11:31