Super Purchasing for Chamber Furnace For Homogenizing - Resistance Flexible Graphite Ring Rroduct for Aluminium billet casting – ZheLu

Super Purchasing for Chamber Furnace For Homogenizing - Resistance Flexible Graphite Ring Rroduct for Aluminium billet casting – ZheLu Detail:

1.Select the hot-top casting equipment platform installation accessories of the corresponding specifications;

2.install the distribution plate, sleeve, adapter plate, distribution groove, and high-purity graphite ring on the upper side of the platform, and install the sleeve, adapter plate, and graphite ring on the mold.

On the inside, ensure clean, no damage and no gaps. It is best to use ceramic fiber paper or ceramic fiber blanket to seal the sides and bottom, which is helpful for thermal insulation.

3.After the overall hot top casting platform is installed, evenly preheat the installed standard equipment platform to 260-350 ℃, by electricity or gas. No open flame should contact the lining body of the product, Otherwise, the crack damage that occurs shall be borne by the user.

4.remove adsorbed crystal water, Make it safe and efficient use

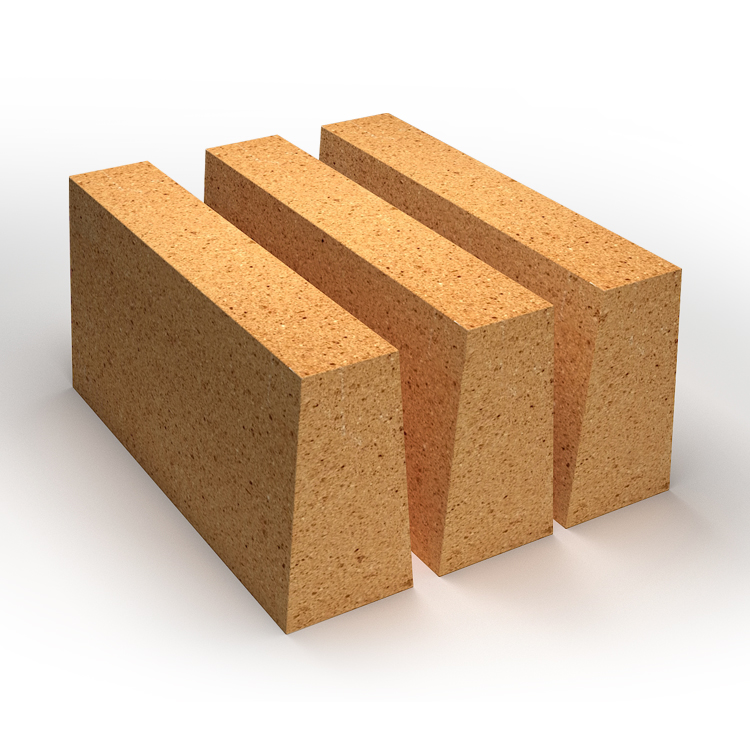

Product detail pictures:

Related Product Guide:

We have a minimum capacity of 500KG medium frequency furnace, electric furnace, etc. for aluminum plants with small output, and there are also fixed large-scale aluminum melting roads with a capacity of 5UST to 88UST, for aluminum casting plants with larger output. Super Purchasing for Chamber Furnace For Homogenizing - Resistance Flexible Graphite Ring Rroduct for Aluminium billet casting – ZheLu , The product will supply to all over the world, such as: Marseille, Melbourne, Turkey, Foshan Zhelu- solution of aluminum profile powder coating production line.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.