saw blade on puller machine to saw aluminum profile

Carbide saw blades include many parameters such as the type of alloy cutter head, the material of the base body, diameter, number of teeth, thickness, tooth shape, angle, aperture, etc. These parameters determine the processing capacity and cutting performance of the saw blade. When selecting a saw blade, the type of sawing material, thickness, sawing speed, sawing direction, feeding speed, and sawing road width need to be selected.

1. Carbide High-speed sawtooth shock resistance Cemented

Carbide has a series of excellent properties such as high hardness, high wear resistance, good toughness, heat resistance and corrosion resistance.

2. High cutting rate, stepped flat tooth Cutting various aluminum profiles

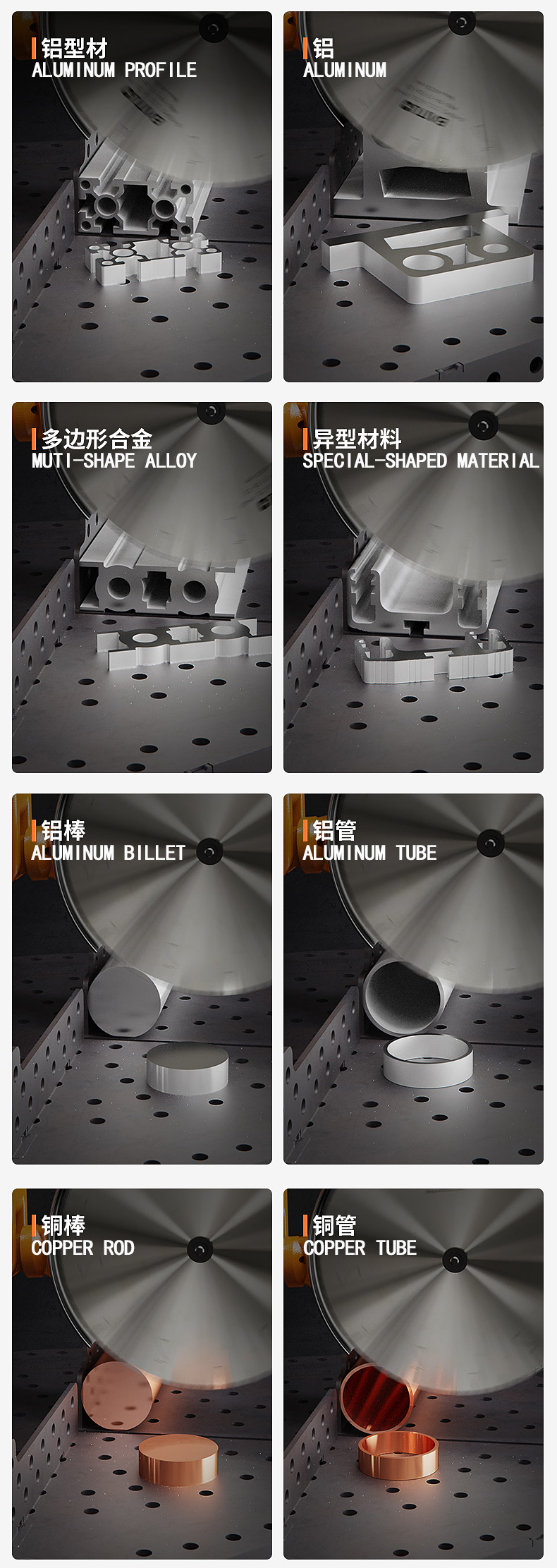

The saw blade ladder and flat teeth are scientifically designed to ensure the sharpness of the saw blade, which is convenient for cutting and cutting various aluminum profiles, aluminum plates, and aluminum rods.

3. The cut surface is smooth and free of burrs Safe cutting without burst edge

Made of 75CR1 steel plate, strong bending resistance and sharp blade Cut finished products without burrs.

4. Muffler hole cooling design Quiet shock-proof wire design

the aluminum plate is injected with shock-absorbing and energy-attenuating polymer, lower noise and less cutting dust provide a good and safe working environment.

5. Strong resistance to external force and thermal stress Safe cutting without burst edge

Made of 75CR1 steel plate, strong bending resistance, sharp blade, no burr on the finished product.

6. Fast cutting efficiency, can cut all kinds of aluminum products

The left and right teeth of the saw blade are scientifically designed to ensure the sharpness of the saw blade, which is convenient for cutting and cutting various soft and hard wood materials.

7. Aviation-grade mouthguards reduce saw wear

Each saw blade is equipped with a protective cover, which will not rust for a long time, protect the saw blade from oxidation, and resist impact and oxidation.