Porthole Die - China Manufacturers, Suppliers, Factory

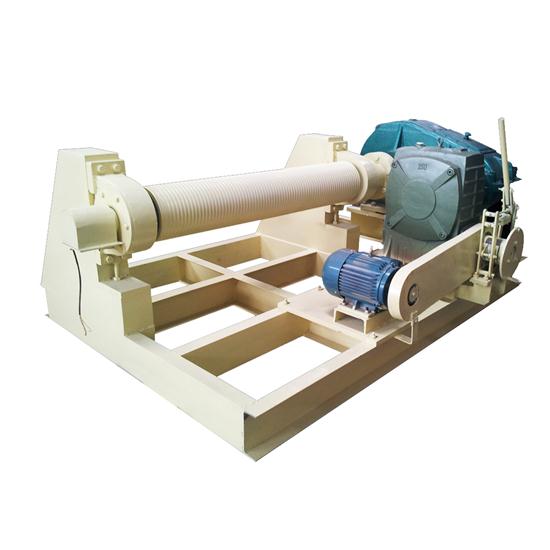

We have a minimum capacity of 500KG medium frequency furnace, electric furnace, etc. for aluminum plants with small output, and there are also fixed large-scale aluminum melting roads with a capacity of 5UST to 88UST, for aluminum casting plants with larger output. Porthole Die, Distributing Launder, Powder Painting Line, Nitriding Equipment,Billet Manufacturing Process Pdf. Aluminum casting process: The recycled aluminum scrap is to be heated and melted in an aluminum melting furnace,add with pure aluminum ingot, with refining flux and dross flux, the impurities will be removed, Then silicon and magnesium will be put into molten aluminum ,After flowing into launder and filter box,the molten aluminum finally reach the ingot casting line, with stacking robot, aluminum ingot will be stacked and packaging. While aluminium billet is another casting equipment, molten aluminum flows into Hot top casting plate, after cooling and Lifting and lowering of pallets, the billet will be made under the plate, then aluminum billet is hoisted out by the crane and enters the homogenization furnace, finally cut by saw. The product will supply to all over the world, such as Europe, America, Australia,Lithuania, San Francisco,Puerto Rico, kazan.Foshan Zhelu is always Contributing to the achievement of carbon neutrality goals in the non-ferrous metal industry.

Related Products