Ceramic foam filters are also called aluminium casting porous ceramic foam filter. The application of ceramic foam filters in aluminum casting is a critical accessories in ensuring quality and purity in the production process. Made of refractory materials, these filters have a porous structure that effectively filters molten aluminum, resulting in cleaner, higher quality castings.

One of the key reasons why ceramic foam filters are favored in aluminum casting is their ability to effectively remove inclusions from molten aluminium. Making use of the principle of adsorption as a filtration mechanism, effectively remove impurities and unwanted elements that could influence the quality of the final product. In addition, the ceramic foam filter can also absorb micron-sized inclusions, and even filters with the same mesh size can ensure high filtration accuracy.

Another significant reason of using ceramic foam filters is their ability to reduce slag and minimize contamination in molten aluminium. Slag is a by-product of the smelting process that can contaminate the molten metal and cause defects. By using a ceramic foam filter, these inclusions are effectively captured, resulting in cleaner, more refined aluminum.

Ceramic foam filters also exhibit excellent thermal shock resistance, filters can withstand rapid temperature swings without cracking, ensuring durability and longevity during production. In addition, the corrosion resistance has been improved, which further extends its service life, allowing it to effectively filter molten aluminum for a long time.

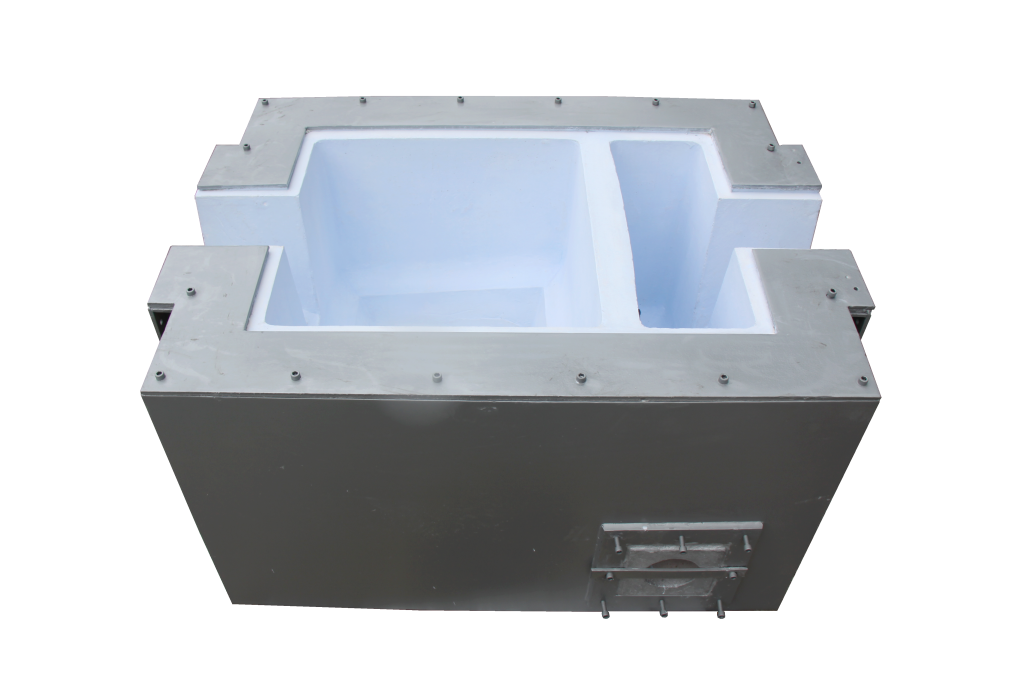

In terms of production efficiency, ceramic foam filters have significant advantages. They are manufactured through an automated assembly line system ensuring consistent quality and accurate size specifications. The filter size is accurate and more compatible with the filter box, ensuring a seamless fit during casting. This standardized production process also saves time.

Overall, the application of ceramic foam filters in aluminum casting has many advantages. From superior filtration capabilities to the ability to reduce contamination and improve thermal shock resistance, these filters play a vital role in ensuring the production of high quality and defect-free castings. With its automatic assembly line production, precise size and compatibility with filter boxes, ceramic foam filters provide a reliable and efficient solution for the aluminum casting industry.

Post time: Jul-27-2023