Manufacturer for Metal Extrusion Machine - High quality Adc12 99.7 A7 A Grade Aluminum alloy Ingots – ZheLu

Manufacturer for Metal Extrusion Machine - High quality Adc12 99.7 A7 A Grade Aluminum alloy Ingots – ZheLu Detail:

After all the charge is melted, stir well and take samples for analysis. Calculate the addition amount of fast-melting silicon according to the analysis results. When the molten aluminum reaches 740-770 °C (the process of adding silicon is an endothermic reaction, the temperature of the molten metal must be heated to keep the temperature not lower than 740 °C), throw the instant silicon agent on the molten aluminum surface for use, and press the bell into the molten aluminum. Stir in for 2-5 minutes. Product description: The silicon content is 95%, and it can be rapidly melted at low temperature, which greatly reduces the cost of alloy ingredients, and can quickly prepare any silicon-aluminum alloy with silicon content; the composition control is extremely precise, and a large number of inclusions and harmful substances that are easily brought into the master alloy are eliminated. Impurities, to avoid the use of waste miscellaneous aluminum to prepare aluminum-silicon master alloys and the impact on the quality of the final aluminum alloy that is difficult to control.

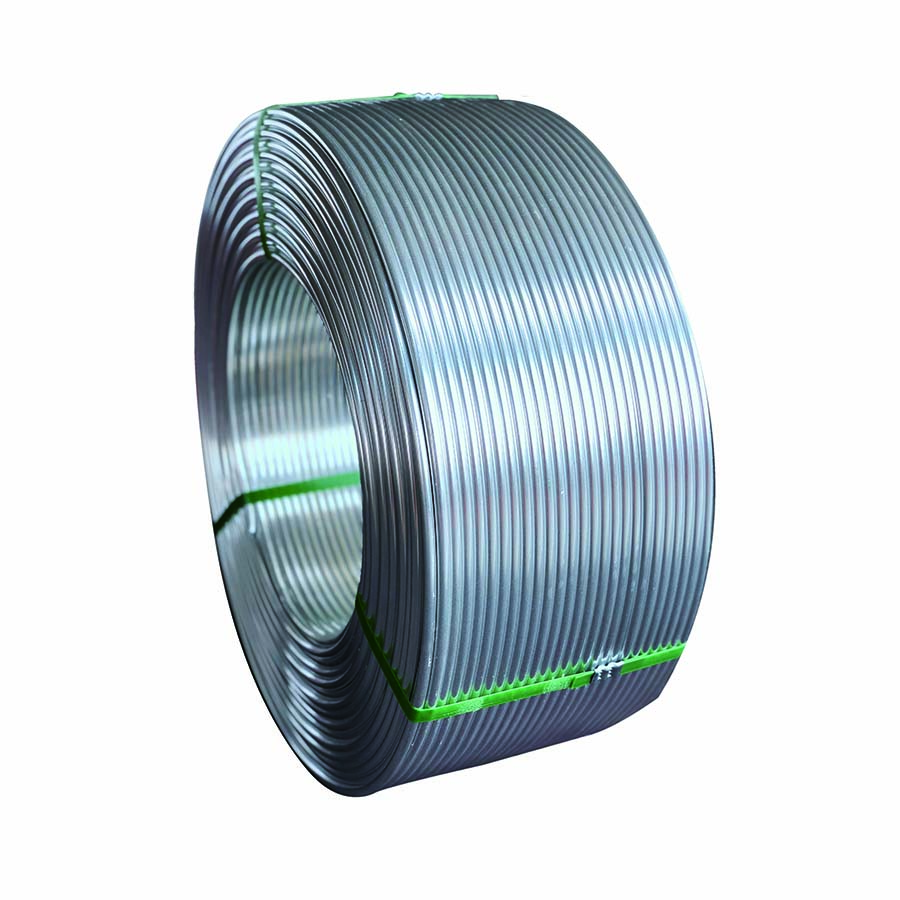

Product detail pictures:

Related Product Guide:

The company was born in Dali, the first town of aluminum in China, which is also a famous town of non-ferrous metals in China, and has more than 1,500 aluminum enterprises so far. Manufacturer for Metal Extrusion Machine - High quality Adc12 99.7 A7 A Grade Aluminum alloy Ingots – ZheLu , The product will supply to all over the world, such as: Mauritius, Uruguay, Singapore, Foshan Zhelu is always Contributing to the achievement of carbon neutrality goals in the non-ferrous metal industry.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.