Manufactur standard Lining Furnaces - High quality Adc12 99.7 A7 A Grade Aluminum alloy Ingots – ZheLu

Manufactur standard Lining Furnaces - High quality Adc12 99.7 A7 A Grade Aluminum alloy Ingots – ZheLu Detail:

After all the charge is melted, stir well and take samples for analysis. Calculate the addition amount of fast-melting silicon according to the analysis results. When the molten aluminum reaches 740-770 °C (the process of adding silicon is an endothermic reaction, the temperature of the molten metal must be heated to keep the temperature not lower than 740 °C), throw the instant silicon agent on the molten aluminum surface for use, and press the bell into the molten aluminum. Stir in for 2-5 minutes. Product description: The silicon content is 95%, and it can be rapidly melted at low temperature, which greatly reduces the cost of alloy ingredients, and can quickly prepare any silicon-aluminum alloy with silicon content; the composition control is extremely precise, and a large number of inclusions and harmful substances that are easily brought into the master alloy are eliminated. Impurities, to avoid the use of waste miscellaneous aluminum to prepare aluminum-silicon master alloys and the impact on the quality of the final aluminum alloy that is difficult to control.

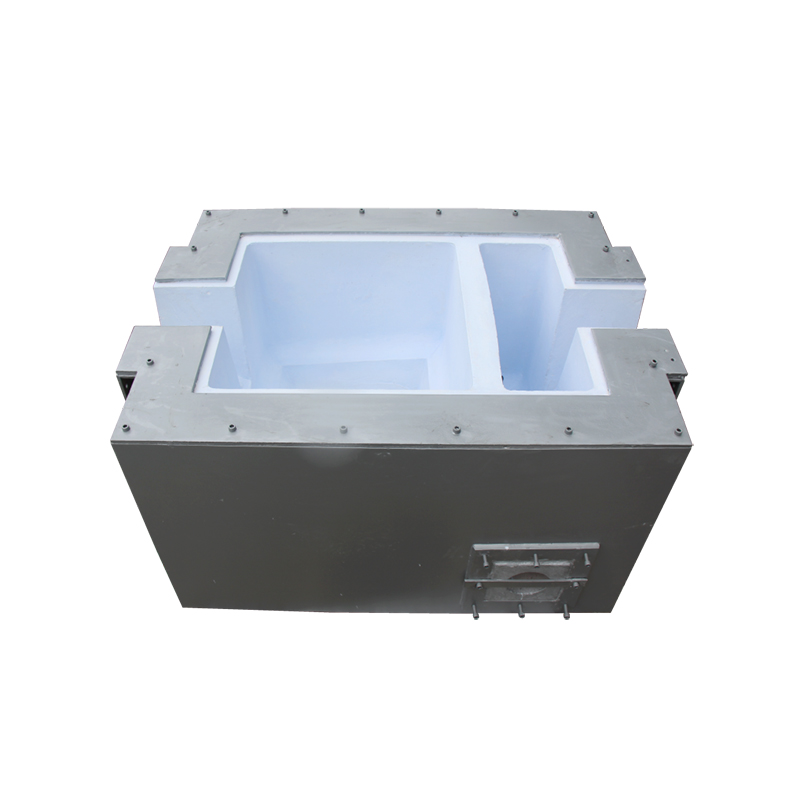

Product detail pictures:

Related Product Guide:

Foshan Zhelu Trading Co., Ltd. is a high-tech enterprise dedicated to the business, trade and technology development of consumables and equipment in the aluminum casting and extrusion industry. The company has a high-quality professional and technical research and development team engaged in aluminum equipment research and development all year round, with strong technical force, and has a number of qualified software and hardware engineers and professional product development designers. The company has advanced product production facilities and testing instruments, has an excellent marketing team and domestic regional channel partners, and has a sound management plan for product market development and product after-sales service. Sales network and product sales agencies all over the country. Strong, professional R & D team and advanced, perfect sales service concept, so that our company's products have a high reputation and market share at home and abroad. At the same time, we will, as always, adhere to the principle of reputation first, customer first, always put the interests of customers first, and wholeheartedly provide the best products and the best quality service for each of our customers. Manufactur standard Lining Furnaces - High quality Adc12 99.7 A7 A Grade Aluminum alloy Ingots – ZheLu , The product will supply to all over the world, such as: Bangalore, Mumbai, Qatar, Foshan Zhelu has successfully developed 6 series aluminum alloy profile products with high strength and high corrosion resistance, which can be used in ships and other fields.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!