Low price for Polyester Felt Pad - aluminum profile clamping iron clips for anodizing – ZheLu

Low price for Polyester Felt Pad - aluminum profile clamping iron clips for anodizing – ZheLu Detail:

Selected materials, stainless steel manufacturing, meticulous workmanship, excellent quality, five advantages to provide you with a better experience

1. Strong clamping force

2. Wear-resistant and durable

3. Sturdy and crash-resistant

4. Reduce costs

5. Long life.

Professional design of spring structure: sufficient elasticity, stable clamping, employees can easily hold the aluminum profile Reduce labor intensity: launched a variety of vertical spraying line products to meet customer requirements, improve efficiency and increase production capacity Environmental protection, energy saving and recycling: environmental protection and energy saving save costs and increase economic benefits. The hanging product runs stably during production, reducing quality problems such as chromatic aberration, collision and sparks, and other potential safety hazards

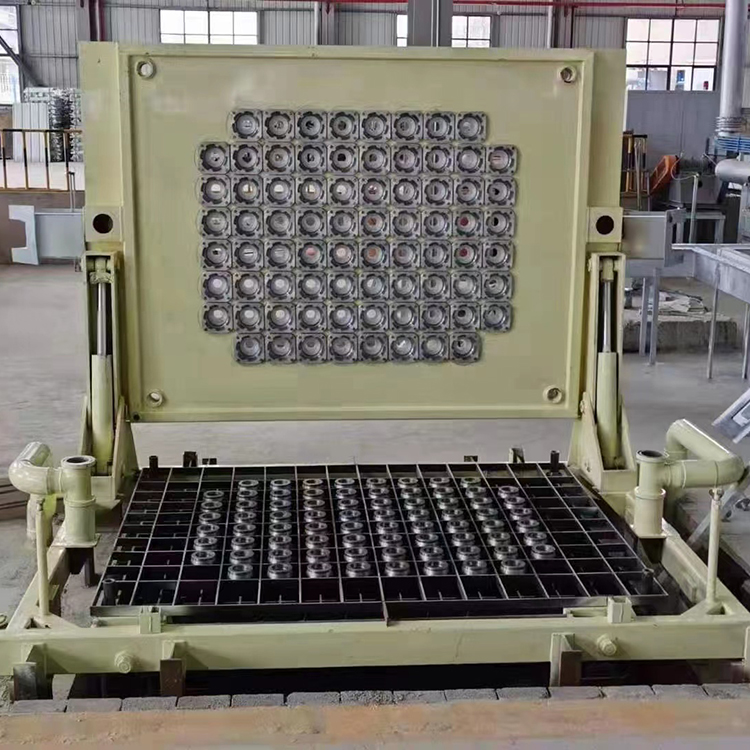

Product detail pictures:

Related Product Guide:

Our complete line solutions include: aluminum alloy ingot/Billet production line and aluminum extrusion production line. Low price for Polyester Felt Pad - aluminum profile clamping iron clips for anodizing – ZheLu , The product will supply to all over the world, such as: Spain, Philippines, Kuwait, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.