Liquid Aluminum Launder - China Factory, Suppliers, Manufacturers

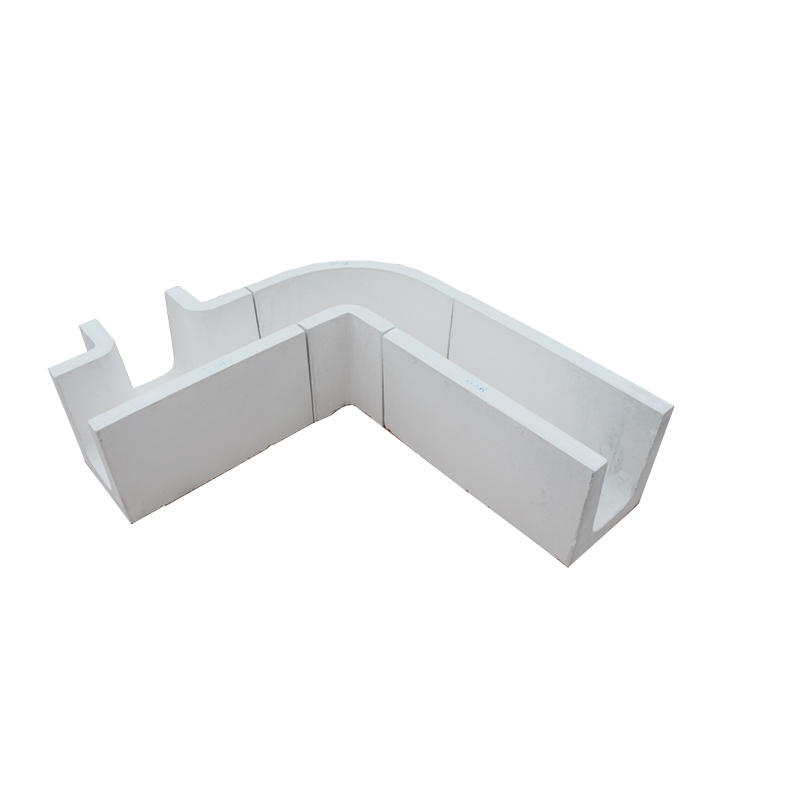

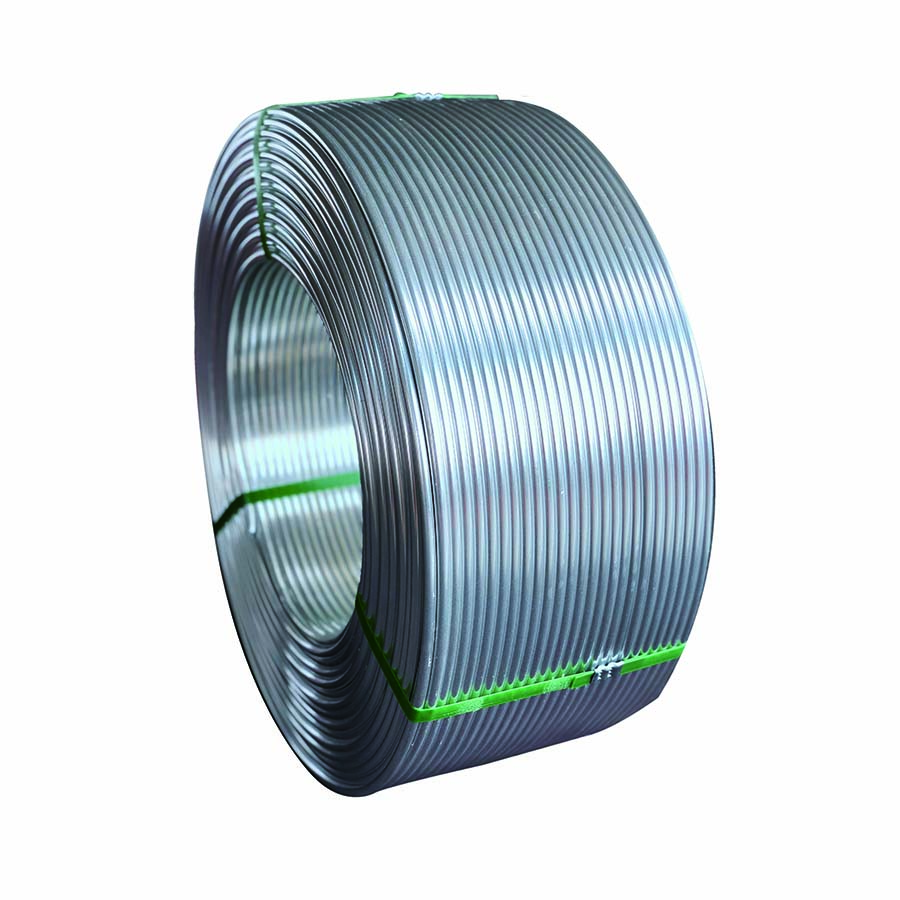

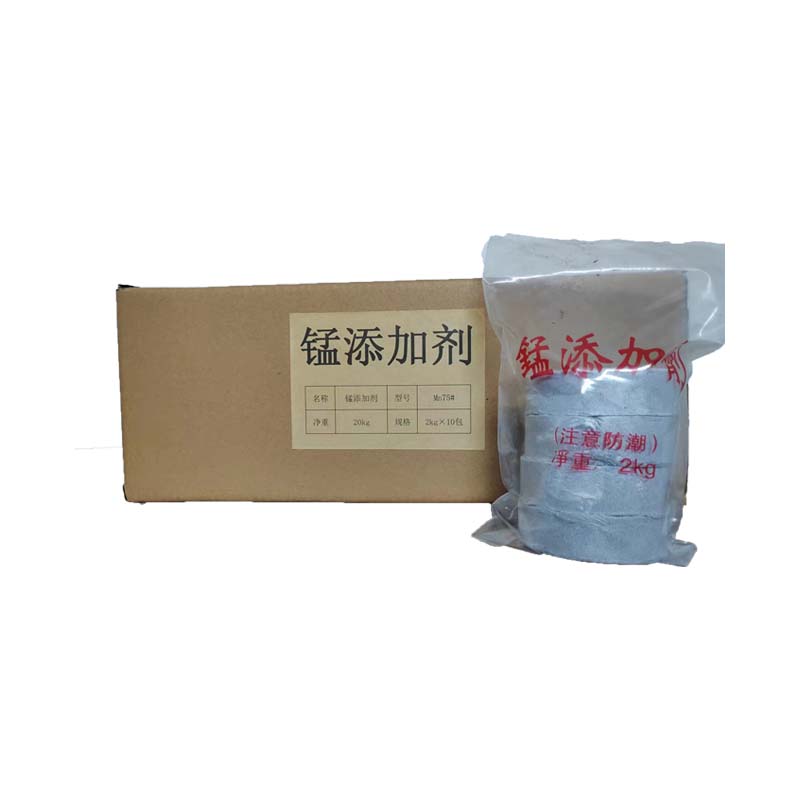

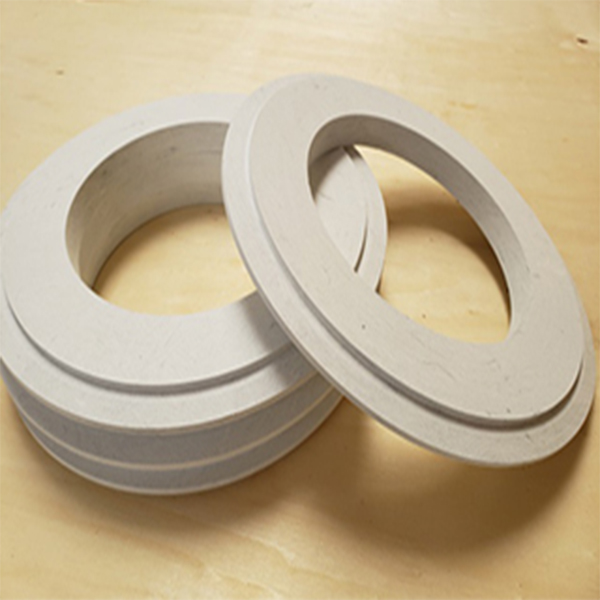

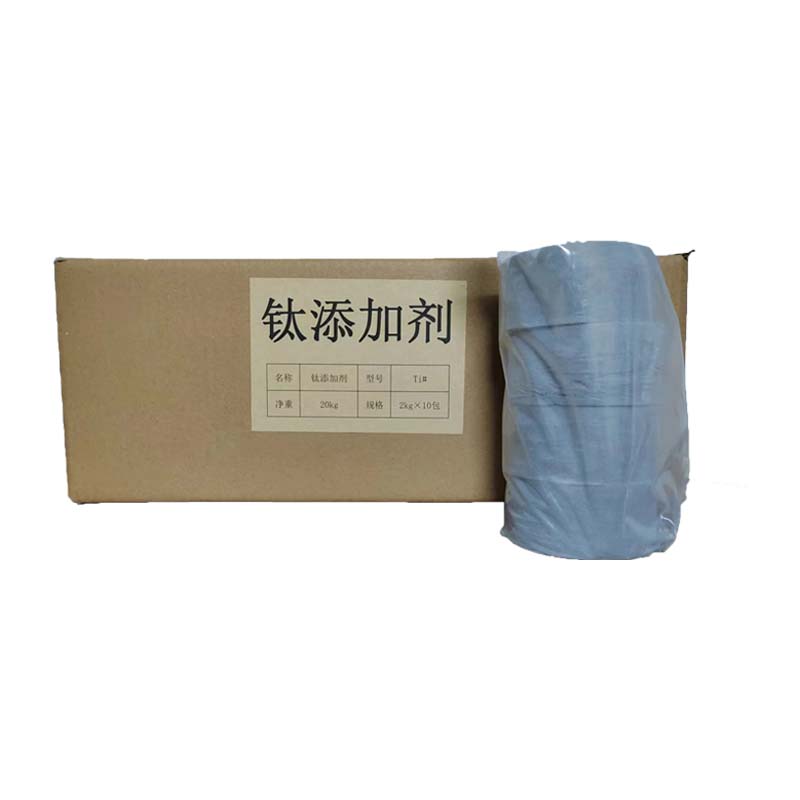

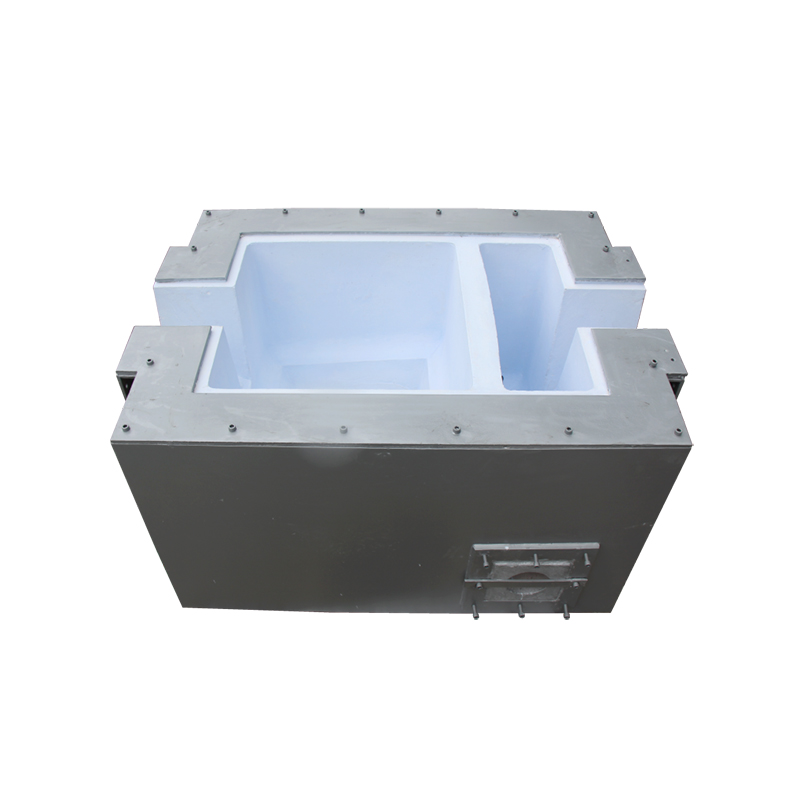

We can fully provide all the materials and accessories used in the production of aluminum ingot production and aluminum rod, including aluminum melting furnace equipment, launder, filter box, online degassing equipment, hot top casting, aluminum ingot casting production line, stacking ingot robot, dust removal equipment, ash stir-frying machine, ball mill, etc., out of the casting industry, the post-processing link of aluminum rod - aluminum profile extrusion, we can also provide products. Aluminum extruder, single rod heating furnace or multi-rod heating furnace, mold heating furnace, mold nitriding furnace, hydraulic oil cooler, cold bed, straightening machine, traction machine, online quenching, aging furnace, air compressor and other equipment, as well as graphite plate, mold, high temperature drum, ring belt, felt sleeve and other consumable materials. Liquid Aluminum Launder, Vacuum Varying Pressure Nitriding Furnace, Sealing Agent, Aluminum Extrusion Machinery,Extrusion Dye. Equipment in the extrusion line, Foshan Zhelu has complete supply chain of aluminum extrusion. The product will supply to all over the world, such as Europe, America, Australia,Belgium, Surabaya,Eindhoven, Manila.Aluminum is the metal of the future, it is not only environmentally friendly, light weight, natural corrosion resistance, high strength, but also good thermal and electrical conductivity.Characteristics of aluminum profiles: durable. Aluminum's corrosion resistance, corrosion resistance and weathering resistance are among its most significant advantages. Aluminum does not require additional treatment to rust naturally and resist corrosion. This is due to the presence of a thin, naturally occurring protective film of alumina on its surface. Through anodizing, its corrosion resistance becomes stronger.

Related Products