Hot Top Billet Continuous Casting Machine For Aluminum Foundry

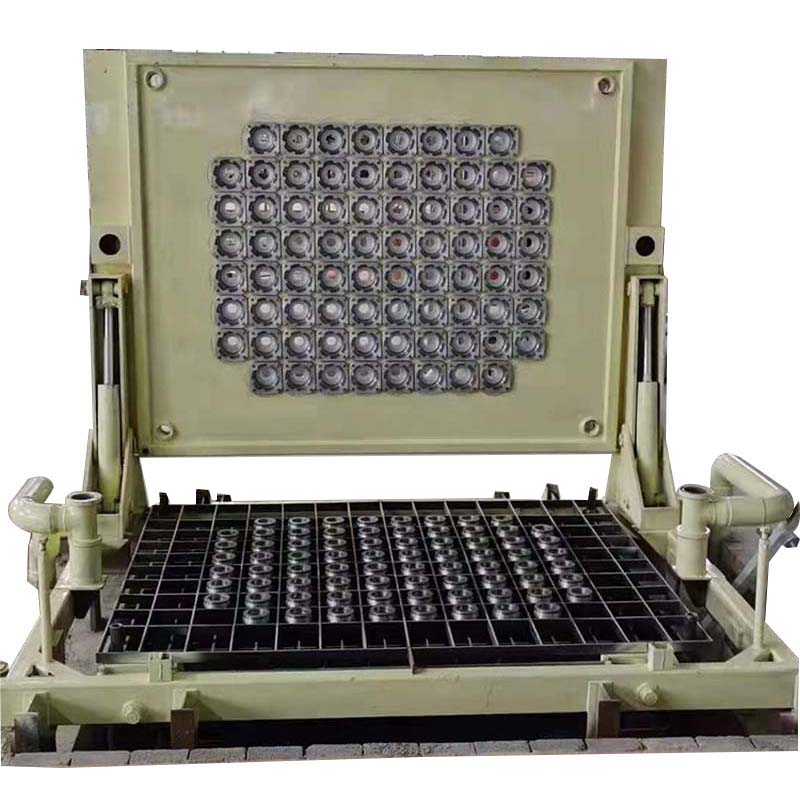

Consist of puller, hydraulic cable, well rack, lifter, steel rope, guiding roller system.

Puller is made of motor, big gear reducer, steel rope, rack etc.

Hydrauclic table is made of hydraulic power pack, tank, turning table, pipe and valves etc.

Hydraulic table installed besides rack, upper mould is installed on hydraulic table, lower mould is installed lifter rack, during casting, lifter will be puller to low limit, then go to height limit to finish cating through steel rope.

Place of Origin: Guangdong, China

Condition: New, New

Machine Type: casting machine, die casting machine

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2020

Warranty of core components: 1 Year

Core Components: Gearbox, Motor, Gear, Pump

Voltage: 380V, 50HZ

Warranty: 1 Year

Key Selling Points: Easy to Operate

Showroom Location: None

Applicable Industries: Manufacturing Plant

Weight (KG): 5000

Billet length: 6 meters

Billet diameter: 70-406mm

billet diameter: 3-16 inch

casting method: hot top casting, air slipper casting, oil slipper casting

Application: Foundry Industry

Usage: Round Bar

Type: Horizontal Continuous Casiting Machine

Technology: Automatic Mold Adjustment

Casting machine adopts casting system (level close-packed hot-top), targets in right position with dummy bar automatically, and is free from silicic acid paper.

1. Casting speed is 0-250 mm/min (Stepless speed regulating). There is assorted anti-speed system with 5-kw traction power.

2. After completion of casting, casting table can flip to 89°C on the plate by stable hydraulic transmission system.Automatic Billet Casting Machine.

3. Casting machine adots casting gystem (level dlose-packed hot. top), targetis Im right postlon with dumy bar automatball and i free from icic acid paper.

4. Casing speed s 0-250 mm/min (Stepless speed regulaling}. There s assorted antl-speed system wih 5-kw racton power.

5. Aftor complrton of caˢing, casting table can flip to 89*C n the plate by stable hydroulice tra nmisson system.

|

Moded Nio. |

Bllet Size Da. x uength (mm) |

Bllet qty (pcs) |

Power (liw) |

Weight per time (k) |

Tting Angle(") |

Well She Lx W (mm) |

|

ALM-ZB3.5" |

90*6000 |

54 |

B |

5562 |

0-89 |

1900* 1900 |

|

ALMZB5" |

0127*5000 |

32 |

B |

5859 |

0-89 |

1800* 1800 |

|

AM-Z86" |

01 52*6000 |

20 |

|

5876 |

0-89 |

1600*1600 |

|

AM-287" |

178*6000 |

16 |

|

6446 |

0-89 |

1600* 1600 |

|

M-288 |

9203*6000 |

12 |

B |

6288 |

0-89 |

1600* 1600 |

|

ALM-209" |

9230*6000 |

8 |

B |

5382 |

0-89 |

1600* 1600 |

|

A M-2B3.5" |

090*6000 |

100 |

11 |

10300 |

0-89 |

2400* 2400 |

|

AUM-2B5" |

*127*6000 |

60 |

11 |

10987 |

0-89 |

2300*2300 |

|

ALMZB5.5" |

0140*6000 |

42 |

11 |

10468 |

0-89 |

2000*2000 |

|

ALM-ZB6" |

152*6000 |

36 |

11 |

10577 |

0-9 |

2000*2000 |

|

AM-2B7* |

178*6000 |

26 |

11 |

10476 |

0-89 |

2100*2100 |

|

ALM-ZB8" ; |

203*6000 |

20 |

11 |

10481 |

0-89 |

1800* 1800 |

|

AM-ZB9* |

230*6000 |

16 |

11 |

10764 |

0一9 |

1800*1800 |

Remarka Technical parameters above are only for your reference. Finallzed detallis are subject to final contract.

1) The same-level hot-top casting plate uses a unified supply and distribution plate to connect multiple hot-top molds, so that the metal liquid level in each mold in the whole set of casting disks is at the same level. In the whole set of casting discs at the same level, the flowing aluminum liquid flows under the previously formed aluminum oxide film, which prevents secondary pollution and oxidative burning of metals.

2) At the same time, in order to make full use of the horizontal plane, the mold can be designed as a densely arranged short mold to realize multi-rod casting.

3) Due to the large amount of molten aluminum and less heat dissipation along the way, the casting temperature can be reduced, so that the crystal subcooling degree is large, the spontaneous nucleation rate is high, and the grains are refined. In addition to the inherent characteristics of short molds, the molten aluminum is The effective crystallization height in the mold is shorter than that of ordinary hot-top casting, the depth of the liquid cavity is shallower, the segregation layer of the cast rod is thinner, the grains are more uniform, and the appearance is smoother.

4) The equipment is assembled as a whole, that is, the casting platform and the dummy base are positioned and combined with each other in advance, and then installed on the chassis of the casting machine and the tilting mechanism, and used together with the wire rope or hydraulic guide column lift.

2. Product advantages

1) Trapezoidal design is adopted for the flow opening of the upper mold shunt plate, which can reduce the phenomenon of hanging aluminum during the liquidation process, thereby increasing the service life of the shunt plate.

2) The upper die plate adopts the integrated design of the guide tube and the adapter plate to avoid the phenomenon of aluminizing and drawing on the surface of the aluminum rod, and at the same time, it can reduce the cost of wearing parts.

3) The internal water circulation cooling is adopted, the heat preservation effect of the diverter plate and the main groove is good, the fluctuation of the liquid level during the casting process is small, and it is not easy to carry slag and slag.