Product Detail

Product Tags

Related Video

Feedback (2)

Foshan Zhelu Trading Co., Ltd. is a high-tech enterprise dedicated to the business, trade and technology development of consumables and equipment in the aluminum casting and extrusion industry. The company has a high-quality professional and technical research and development team engaged in aluminum equipment research and development all year round, with strong technical force, and has a number of qualified software and hardware engineers and professional product development designers. The company has advanced product production facilities and testing instruments, has an excellent marketing team and domestic regional channel partners, and has a sound management plan for product market development and product after-sales service. Sales network and product sales agencies all over the country. Strong, professional R & D team and advanced, perfect sales service concept, so that our company's products have a high reputation and market share at home and abroad. At the same time, we will, as always, adhere to the principle of reputation first, customer first, always put the interests of customers first, and wholeheartedly provide the best products and the best quality service for each of our customers. Aluminum Log, Aluminum Melting Pot, 100 Kevlar Felt Pad, Foshan zhelu trading co., ltd. Aluminum casting and extrusion solution provider, not only the products needed in casing or extrusion, but the service or scheme to improve the working process, making it more effective and steadily.

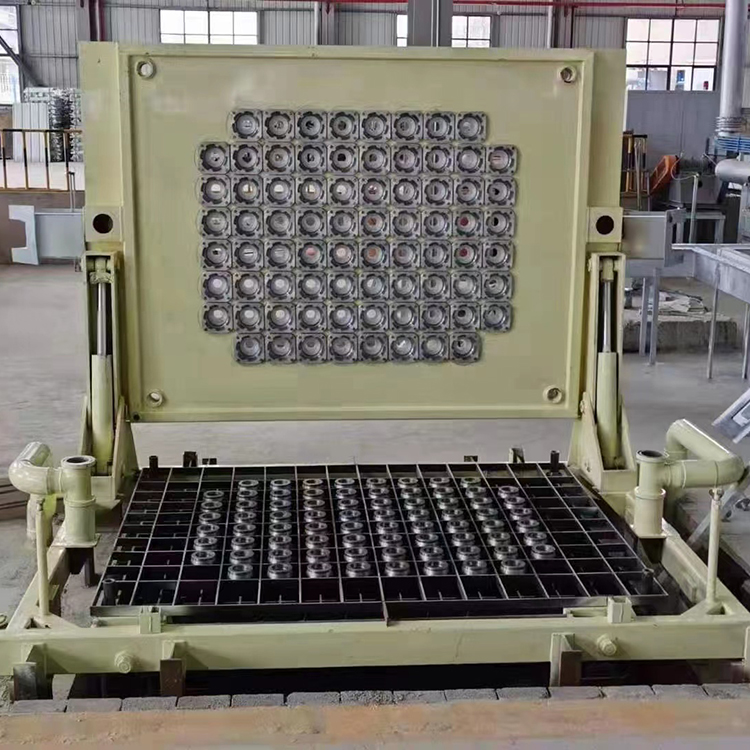

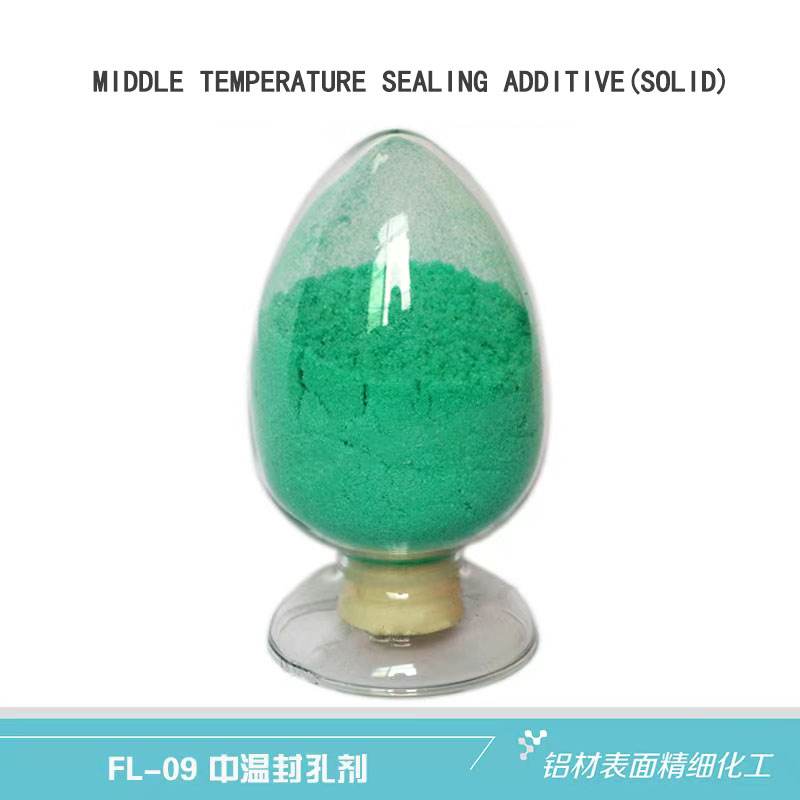

High reputation Melting Furnace For Aluminium - high quality anodizing machine semi auto aluminum anodizing line – ZheLu Detail:

Product detail pictures:

Related Product Guide:

Our complete line solutions include: aluminum alloy ingot/Billet production line and aluminum extrusion production line. High reputation Melting Furnace For Aluminium - high quality anodizing machine semi auto aluminum anodizing line – ZheLu , The product will supply to all over the world, such as: Sevilla, Nepal, Russia, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

By Odelia from Monaco - 2017.09.30 16:36

By Odelia from Monaco - 2017.09.30 16:36

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

By Klemen Hrovat from Croatia - 2018.05.13 17:00

By Klemen Hrovat from Croatia - 2018.05.13 17:00