High Quality Extrusion Die Manufacturer - Sn&Ni Salt Electrolytic Coloring Additive for anodizing – ZheLu

High Quality Extrusion Die Manufacturer - Sn&Ni Salt Electrolytic Coloring Additive for anodizing – ZheLu Detail:

1. Analyze the bath solution daily,determine the concentrations of free sulfuric acid,stannous sulfate, nickel sulfate and total acid,replenish in time.

2. The additions scale of stannous sulfate to Sn&Ni Salt Electrolytic Coloring Additive is 1:1.1~1.2.

3. There will be white precipitations in long-time production, so the bath solution should be filtered and cleaned regularly.

is sealed with polybag, 5kg net each and 4 polybags in carton,20kg net each. Protected from light in a dry place.

Determination of stannous sulfate (SnSO4) content

Required reagents

①1% starch solution ② 0.1N iodine standard solution

Assay steps

Accurately draw 10mL of the test solution into a 250mL triangular beaker, add 100mL of water, add 5mL of 1:1 hydrochloric acid, and then add 5mL of 1% starch indicator, quickly titrate with 0.1N iodine standard solution, the solution turns from colorless to blue The color is the end point, and the volume V of the standard solution consumed is recorded.

calculate

Stannous sulfate (g/L)=10.73 × V × N

Determination of nickel sulfate (NiSO4) content

Required reagents

①30% hydrogen peroxide

②10% potassium sodium tartrate

③ 1:1 ammonia water

④1% purpuric acid amine

2. Assay steps

Take 1mL of coloring bath solution into a 250mL triangular conical flask, add 2mL (30%) hydrogen peroxide, heat to near dryness, add about 80mL water after cooling, 10mL (10%) potassium sodium tartrate, 20mL (1:1) ammonia water, A small amount of 1% ammonium purpurate was titrated with 0.01N EDTA standard solution until the solution turned purple as the end point.

calculate

Nickel sulfate (g/L)=262.9 × V × N Determination of total acid (H, SO)

1. Required reagents

0.1% Bromothymol Blue

② 1NNaOH standard solution 2. Assay steps

Accurately draw 10mL of the test solution into a 250mL triangular beaker, and add about 100mL of water. Add 4 drops of 0.1% bromothymol blue indicator, titrate with 1N NaOH standard solution, change from yellow to cyan as the end point, and record the volume V of NaOH consumed.

3. Calculate the total acid (

g/L)=4.9xVxN

Champagne coloring sink 2 — assay method

Determination of free acid (H2SO4)

Required reagents 1N NaOH standard solution

2. Assay steps

Accurately draw 50mL of the test solution into a 100mL beaker, titrate the pH to 2.1 with 1N NaOH standard solution under the measurement of the acidity meter, and record the consumed volume V.

calculate

Free acid ((g/L)=4.9 × V × N/5

Process parameters

Tin & Nickel Double Salt Electrolytic Coloring

| stannous sulfate | Nickel sulfate | free acid | P H | Voltage | temperature |

| 5~10g/L | 16~20g/L | 16~21g/L | 0.8~1.2 | 14~18V | 1 8~23℃ |

|

stannous sulfate |

free acid |

P H |

Voltage |

temperature |

|

6 to 1 2 g/L |

16~21g/L |

0.8~1.2 |

1 6 ~18V |

1 8~23℃ |

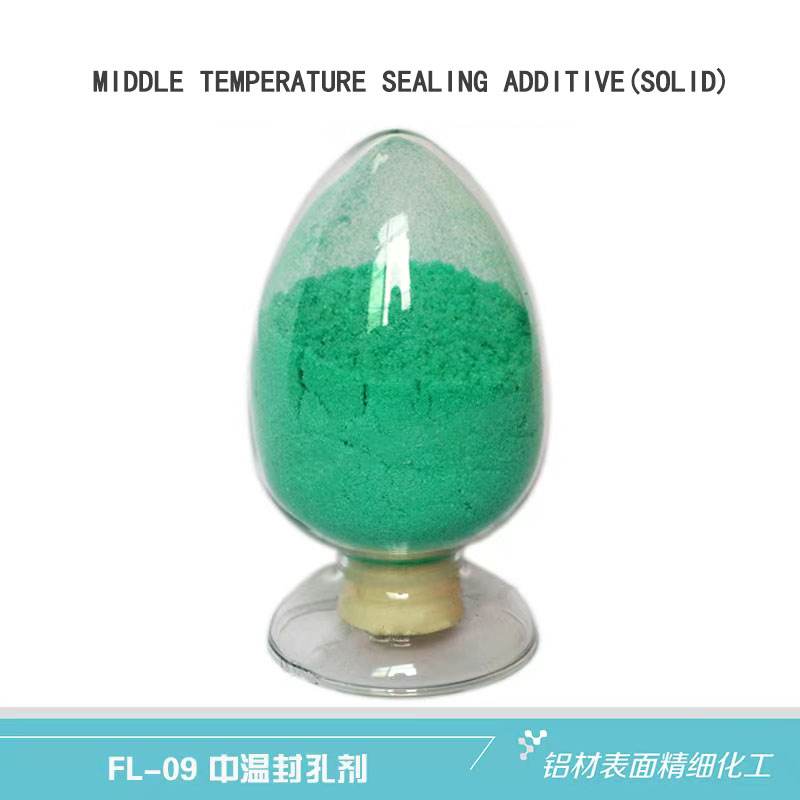

Product detail pictures:

Related Product Guide:

We provide the products with superior quality and competitive prices. High Quality Extrusion Die Manufacturer - Sn&Ni Salt Electrolytic Coloring Additive for anodizing – ZheLu , The product will supply to all over the world, such as: UK, Bangladesh, Bhutan, Aluminum is the metal of the future, it is not only environmentally friendly, light weight, natural corrosion resistance, high strength, but also good thermal and electrical conductivity.Characteristics of aluminum profiles: durable. Aluminum's corrosion resistance, corrosion resistance and weathering resistance are among its most significant advantages. Aluminum does not require additional treatment to rust naturally and resist corrosion. This is due to the presence of a thin, naturally occurring protective film of alumina on its surface. Through anodizing, its corrosion resistance becomes stronger.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.