Welcome to our websites!

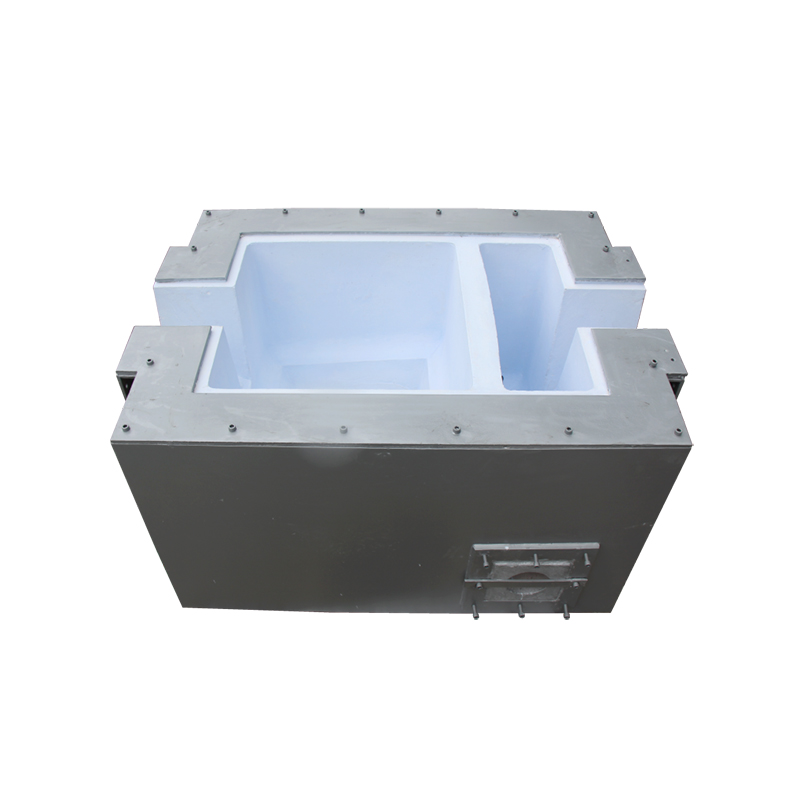

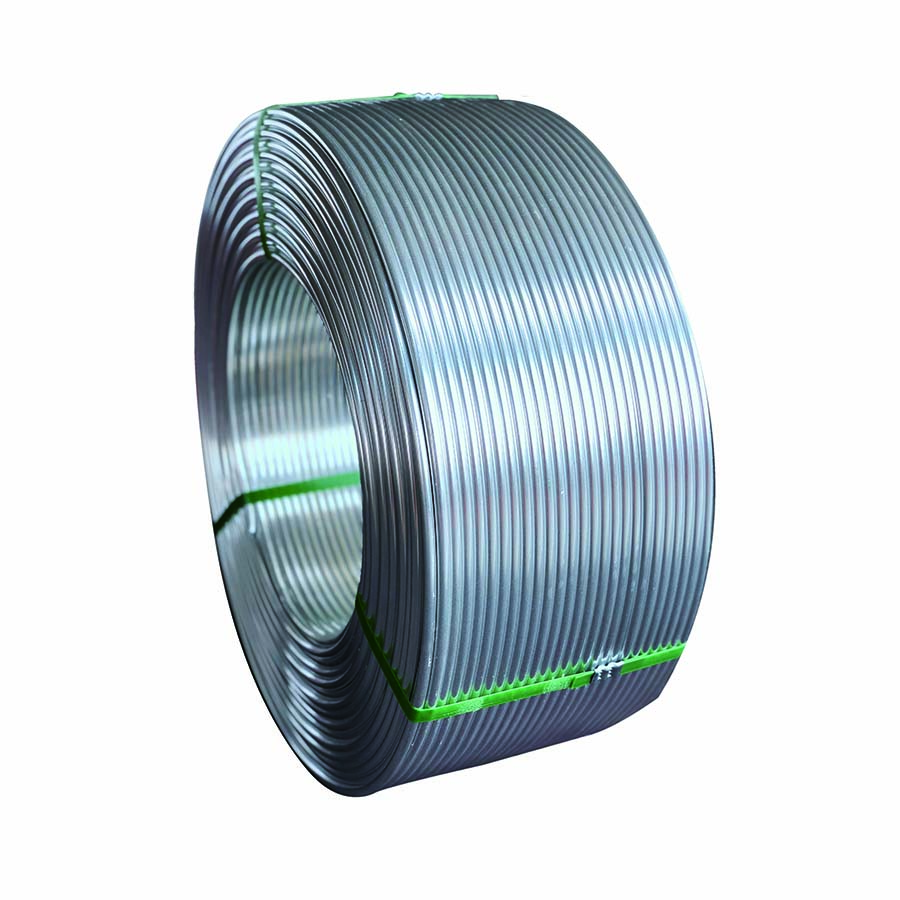

High Performance Vesuvius Furnace - Aluminum Titanium Boron wire metal additive for billet casting – ZheLu

High Performance Vesuvius Furnace - Aluminum Titanium Boron wire metal additive for billet casting – ZheLu Detail:

Product detail pictures:

Related Product Guide:

Foshan Zhelu Trading Co., Ltd. is an export enterprise in the aluminum casting and extrusion industry for more than 20 years, and is also a manufacturer of aluminum casting and extrusion consumable materials. It mainly produces aluminum refining flux, drossing flux, ceramic foam filter plates, aluminum silicate stopper cone, aluminum titanium boron wires, castables, felt sleeves and felt belts and other consumables. More importantly, our company as an aluminum plant service company, to help many overseas enterprises to build a new aluminum ingot / aluminum billet production line, aluminum profile production line, powder coating production line and anodizing production line, with the most professional technology and high-quality products to win the trust and support of all aluminum plants, we have a professional installation engineering team and the most thoughtful commissioning services, to help the new aluminum plant quickly put into production and generate income, our ultimate goal is to let each aluminum plant can obtain their own profit stably and efficiently. High Performance Vesuvius Furnace - Aluminum Titanium Boron wire metal additive for billet casting – ZheLu , The product will supply to all over the world, such as: Congo, Denmark, Jersey, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.