Welcome to our websites!

Good quality Aluminum Heatsink Extrusion - 600-12000T Aluminum Extrusion Press Machine Windows and industrial profile – ZheLu

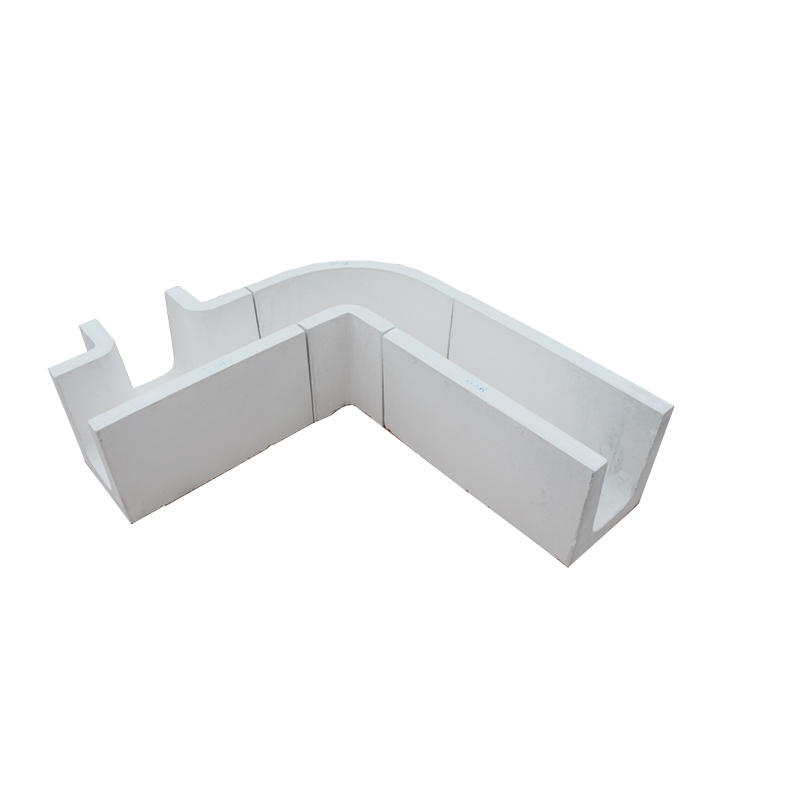

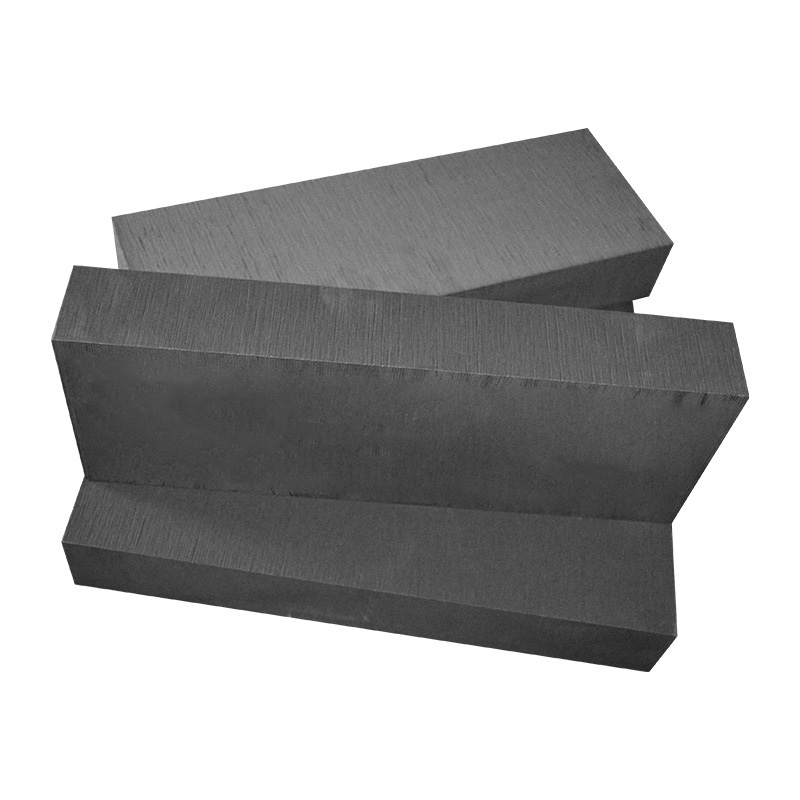

Good quality Aluminum Heatsink Extrusion - 600-12000T Aluminum Extrusion Press Machine Windows and industrial profile – ZheLu Detail:

Product detail pictures:

Related Product Guide:

Our complete line solutions include: aluminum alloy ingot/Billet production line and aluminum extrusion production line. Good quality Aluminum Heatsink Extrusion - 600-12000T Aluminum Extrusion Press Machine Windows and industrial profile – ZheLu , The product will supply to all over the world, such as: Sheffield, Mexico, Victoria, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.