Welcome to our websites!

Fast delivery Extrusion Profile Aluminium - Water Mist Quenching System For Aluminum Profile Extrusion Machine – ZheLu

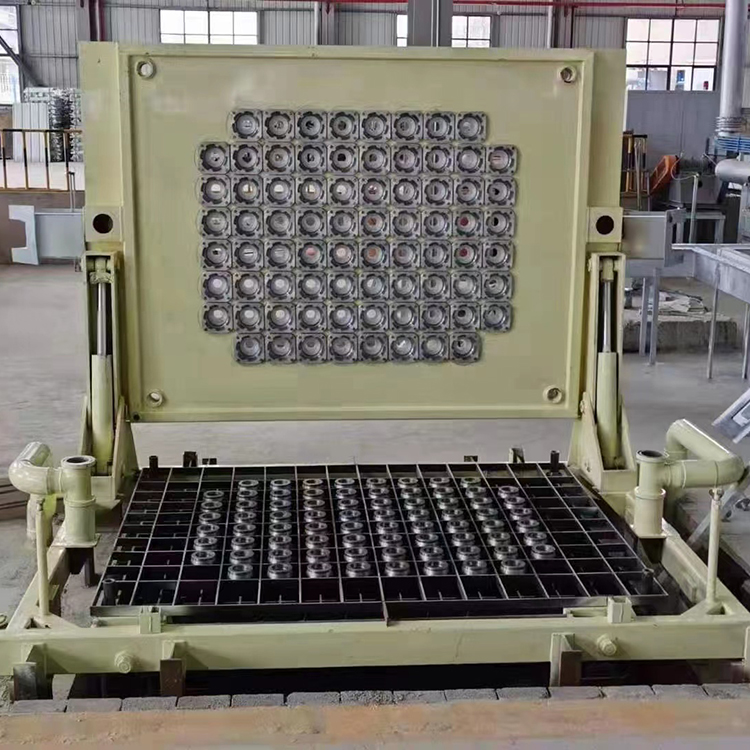

Fast delivery Extrusion Profile Aluminium - Water Mist Quenching System For Aluminum Profile Extrusion Machine – ZheLu Detail:

5. Human-machine interface control and parameter memory function

Man-machine interface control, all actions and adjustments of the system can be controlled through the man-machine interface, which is easy to operate. Parameter memory function, in order to improve the efficiency of adjustment, the control system has designed a parameter memory function. Each reasonable process parameter system can be memorized, and the next time the same product is produced, the system will call the memorized parameters for production. The system has remote debugging, monitoring and maintenance functions.

Product detail pictures:

Related Product Guide:

Our products are mainly used in the smelting process of the aluminum casting industry and the extrusion process of aluminum profiles. Fast delivery Extrusion Profile Aluminium - Water Mist Quenching System For Aluminum Profile Extrusion Machine – ZheLu , The product will supply to all over the world, such as: Uruguay, Brazil, Oslo, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.