Welcome to our websites!

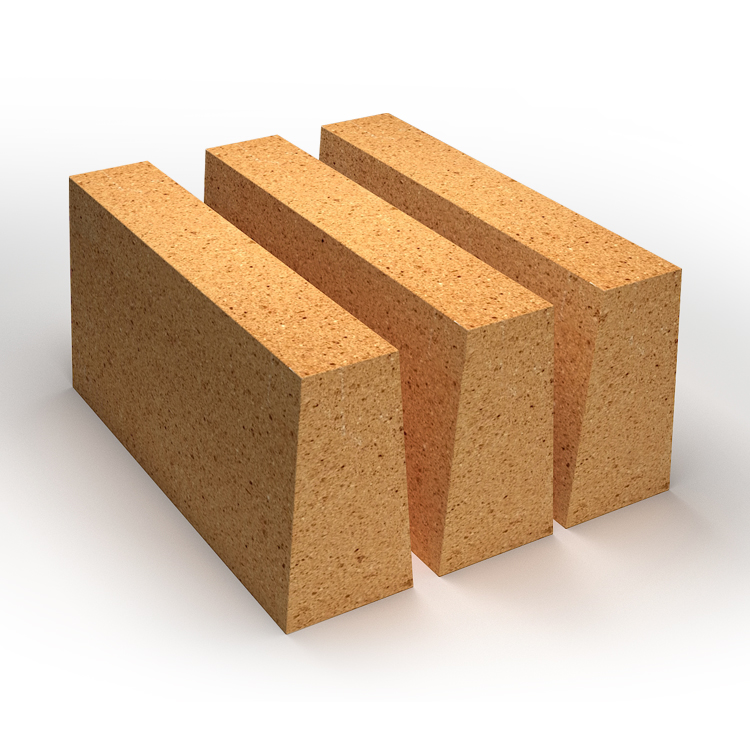

Factory selling Refractory Brick - Different industrial grades talcum powder ingredients for ceramic use – ZheLu

Factory selling Refractory Brick - Different industrial grades talcum powder ingredients for ceramic use – ZheLu Detail:

Product detail pictures:

Related Product Guide:

The global aluminum production market is looking forward to us. In line with the goal of building a grand brand of the enterprise, we adhere to steady operation and long-term development, and at the same time rely on strong human resources, rigorous production management and business philosophy, through the accumulation of our own experience and the unremitting pursuit and improvement of the future, and constantly carry out self-innovation, scientific and technological innovation, management and business philosophy innovation, in line with the trend of today's aluminum product development, to provide you with high-quality, low-priced, more fashionable products. Welcome friends from all walks of life to visit, guide and negotiate business. Factory selling Refractory Brick - Different industrial grades talcum powder ingredients for ceramic use – ZheLu , The product will supply to all over the world, such as: Bandung, Mali, Amsterdam, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.