Factory best selling Liner - Sn&Ni Salt Electrolytic Coloring Additive for anodizing – ZheLu

Factory best selling Liner - Sn&Ni Salt Electrolytic Coloring Additive for anodizing – ZheLu Detail:

1. Analyze the bath solution daily,determine the concentrations of free sulfuric acid,stannous sulfate, nickel sulfate and total acid,replenish in time.

2. The additions scale of stannous sulfate to Sn&Ni Salt Electrolytic Coloring Additive is 1:1.1~1.2.

3. There will be white precipitations in long-time production, so the bath solution should be filtered and cleaned regularly.

is sealed with polybag, 5kg net each and 4 polybags in carton,20kg net each. Protected from light in a dry place.

Determination of stannous sulfate (SnSO4) content

Required reagents

①1% starch solution ② 0.1N iodine standard solution

Assay steps

Accurately draw 10mL of the test solution into a 250mL triangular beaker, add 100mL of water, add 5mL of 1:1 hydrochloric acid, and then add 5mL of 1% starch indicator, quickly titrate with 0.1N iodine standard solution, the solution turns from colorless to blue The color is the end point, and the volume V of the standard solution consumed is recorded.

calculate

Stannous sulfate (g/L)=10.73 × V × N

Determination of nickel sulfate (NiSO4) content

Required reagents

①30% hydrogen peroxide

②10% potassium sodium tartrate

③ 1:1 ammonia water

④1% purpuric acid amine

2. Assay steps

Take 1mL of coloring bath solution into a 250mL triangular conical flask, add 2mL (30%) hydrogen peroxide, heat to near dryness, add about 80mL water after cooling, 10mL (10%) potassium sodium tartrate, 20mL (1:1) ammonia water, A small amount of 1% ammonium purpurate was titrated with 0.01N EDTA standard solution until the solution turned purple as the end point.

calculate

Nickel sulfate (g/L)=262.9 × V × N Determination of total acid (H, SO)

1. Required reagents

0.1% Bromothymol Blue

② 1NNaOH standard solution 2. Assay steps

Accurately draw 10mL of the test solution into a 250mL triangular beaker, and add about 100mL of water. Add 4 drops of 0.1% bromothymol blue indicator, titrate with 1N NaOH standard solution, change from yellow to cyan as the end point, and record the volume V of NaOH consumed.

3. Calculate the total acid (

g/L)=4.9xVxN

Champagne coloring sink 2 — assay method

Determination of free acid (H2SO4)

Required reagents 1N NaOH standard solution

2. Assay steps

Accurately draw 50mL of the test solution into a 100mL beaker, titrate the pH to 2.1 with 1N NaOH standard solution under the measurement of the acidity meter, and record the consumed volume V.

calculate

Free acid ((g/L)=4.9 × V × N/5

Process parameters

Tin & Nickel Double Salt Electrolytic Coloring

| stannous sulfate | Nickel sulfate | free acid | P H | Voltage | temperature |

| 5~10g/L | 16~20g/L | 16~21g/L | 0.8~1.2 | 14~18V | 1 8~23℃ |

|

stannous sulfate |

free acid |

P H |

Voltage |

temperature |

|

6 to 1 2 g/L |

16~21g/L |

0.8~1.2 |

1 6 ~18V |

1 8~23℃ |

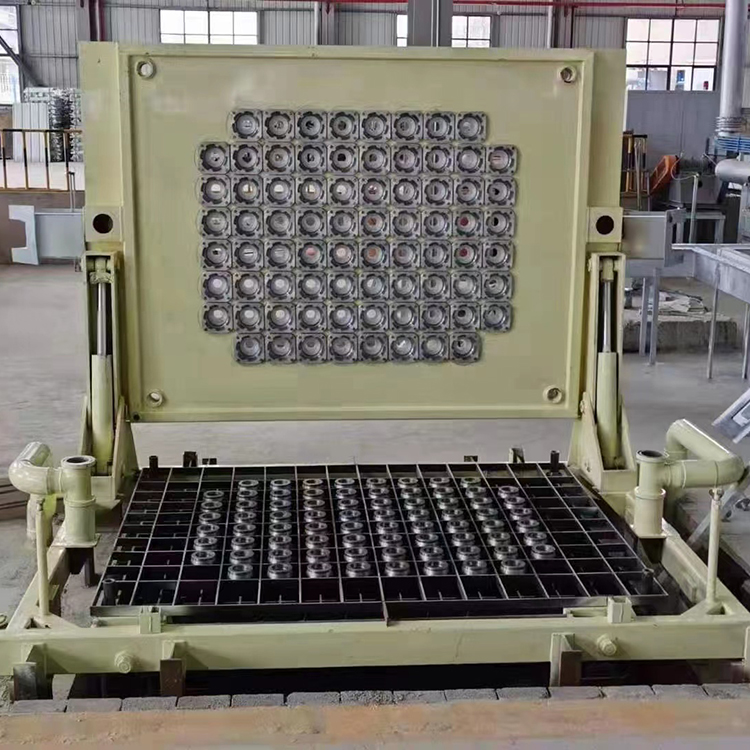

Product detail pictures:

Related Product Guide:

Our products are mainly used in the smelting process of the aluminum casting industry and the extrusion process of aluminum profiles. Factory best selling Liner - Sn&Ni Salt Electrolytic Coloring Additive for anodizing – ZheLu , The product will supply to all over the world, such as: Honduras, Rio de Janeiro, Swedish, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.