extrusion rod or extrusion ram in aluminum extrusion press machine

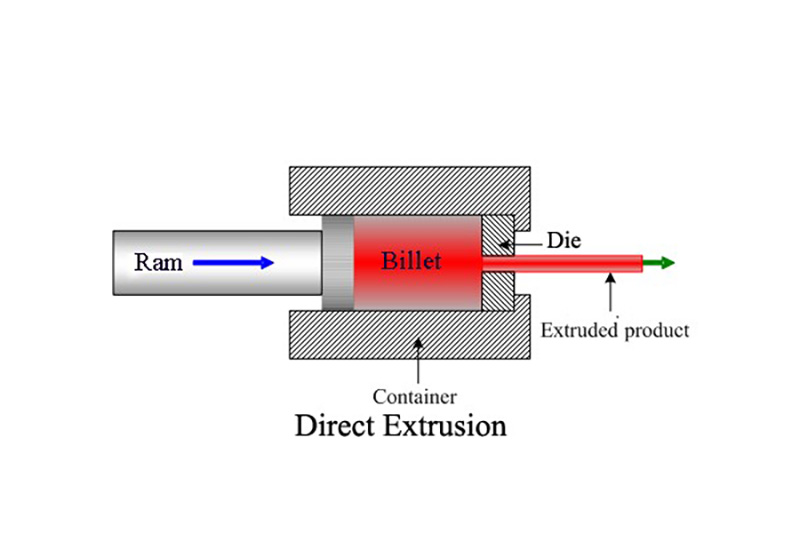

The extrusion ram is divided into two types: hollow and solid. Hollow extrusion rams are used in tube and rod extrusion machines.

The extrusion ram is generally a cylindrical overall structure, which can be divided into ends, shafts and roots.

On large tonnage extruders, the extrusion rams are made of variable section to increase the longitudinal bending strength. At this time, the extrusion cylinder should have an inner hole with a variable cross-section.

The outer diameter of the extrusion ram is determined according to the inner diameter of the extrusion cylinder.

The outer diameter of the extrusion ram of the horizontal extruder is generally larger than that of the extrusion ram. The inner diameter of the cylinder is 4-10mm smaller.

The length of the extrusion ram is equal to the length of the extrusion ram supporter plus the length of the extrusion cylinder plus 5 to 10mm, in order to push the pressure excess (see extrusion residual material) and extrusion gasket out of the extrusion cylinder. The material of the extrusion ram is chrome-nickel-molybdenum and chrome-nickel-tungsten alloy. The assembled extruded rod body is made of chromium-nickel-tungsten-vanadium alloy, and the root is made of chromium-nickel-molybdenum alloy.

The extrusion ram is subjected to great longitudinal bending stress and compressive stress during operation. Therefore, the stability and

strength of the extrusion ram should be checked during extrusion.