Extrusion Press - China Manufacturers, Factory, Suppliers

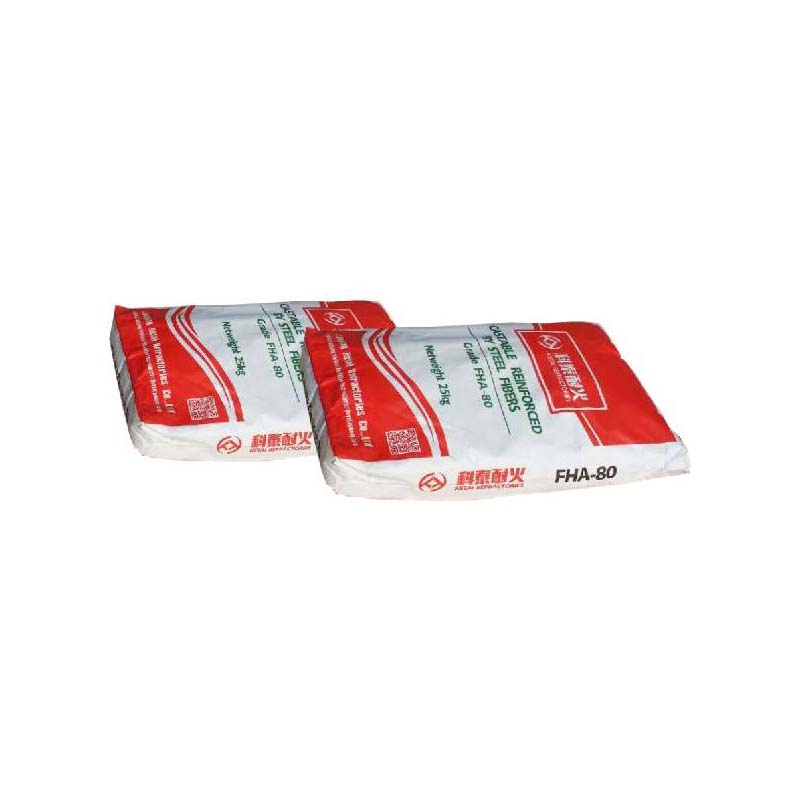

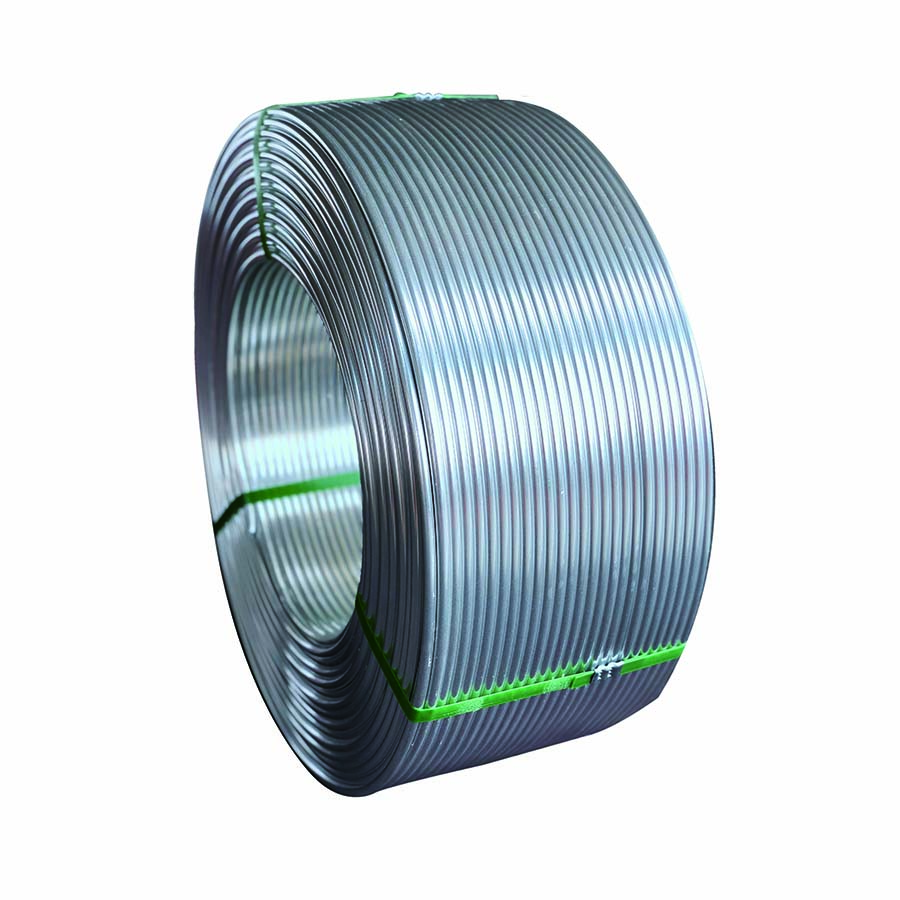

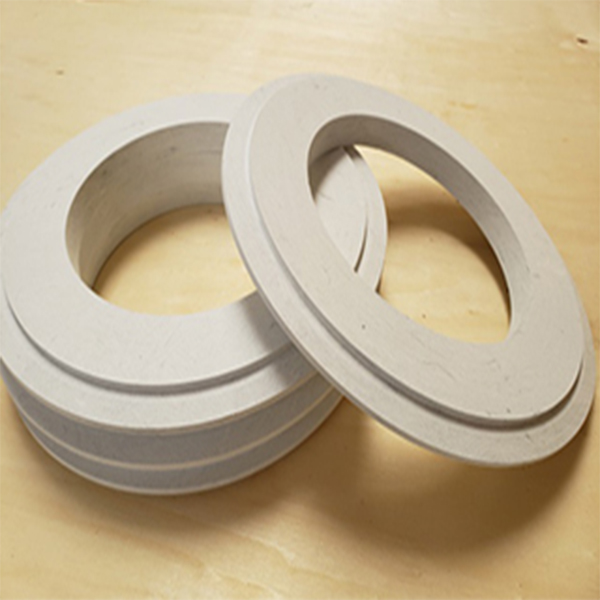

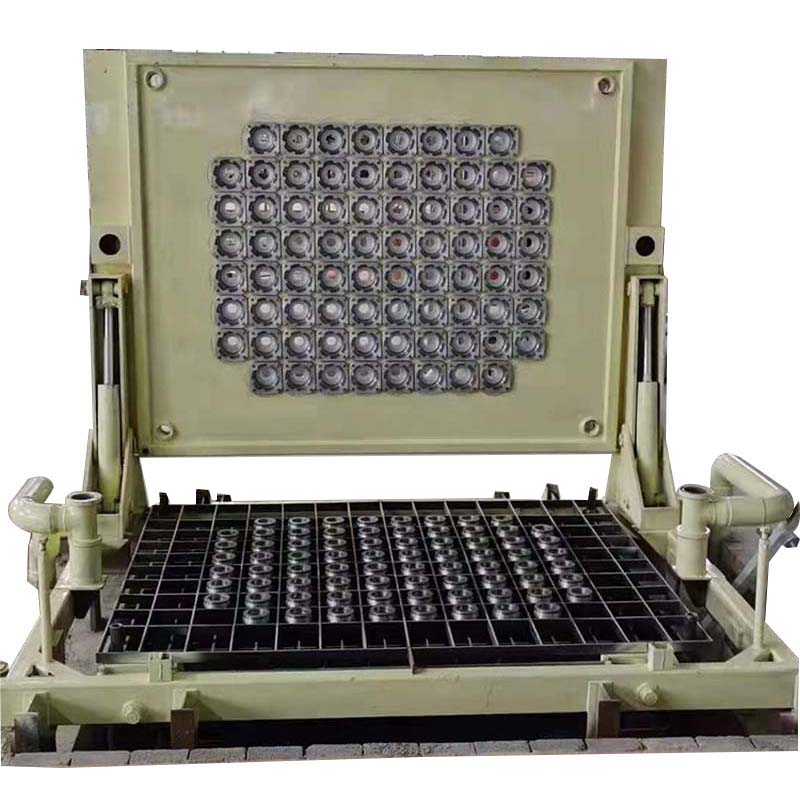

Foshan Zhelu has the most advanced aluminum extrusion process in China, as a service company or solution company, we can help any aluminum plant to solve the current problems, or provide the most complete product service, we can give China's most advanced casting and extrusion process. Extrusion Press, Homogenizing Heat Treatment, Aging Furnace, Large Aluminum Extrusions,Sn&Ni Salt Electrolytic Coloring Additive. Aluminum casting process: The recycled aluminum scrap is to be heated and melted in an aluminum melting furnace,add with pure aluminum ingot, with refining flux and dross flux, the impurities will be removed, Then silicon and magnesium will be put into molten aluminum ,After flowing into launder and filter box,the molten aluminum finally reach the ingot casting line, with stacking robot, aluminum ingot will be stacked and packaging. While aluminium billet is another casting equipment, molten aluminum flows into Hot top casting plate, after cooling and Lifting and lowering of pallets, the billet will be made under the plate, then aluminum billet is hoisted out by the crane and enters the homogenization furnace, finally cut by saw. The product will supply to all over the world, such as Europe, America, Australia,Afghanistan, Mecca,Tunisia, Amsterdam.Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

Related Products