Welcome to our websites!

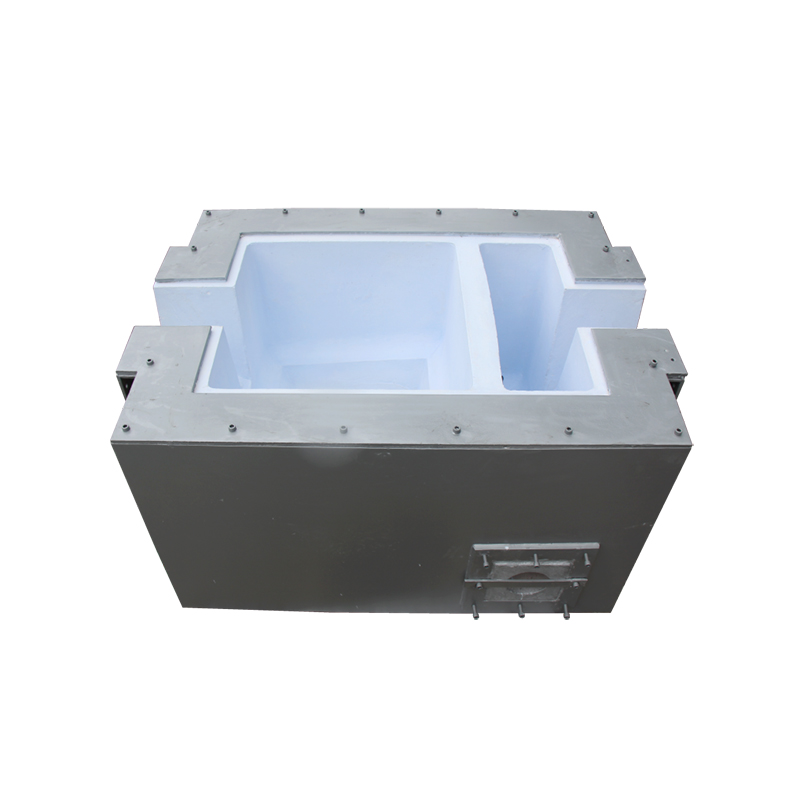

Cheap PriceList for Anodizing Chemials - filter box with ceramic filter board filtering molten aluminum – ZheLu

Cheap PriceList for Anodizing Chemials - filter box with ceramic filter board filtering molten aluminum – ZheLu Detail:

1. It can be used directly at room temperature without worrying about thermal shock.

2. No thermal expansion and low thermal conductivity.

3. It can float in aluminum, reducing the possibility of refractory inclusions.

Product detail pictures:

Related Product Guide:

Our company has the most complete and high effective supply chain in the industry. Cheap PriceList for Anodizing Chemials - filter box with ceramic filter board filtering molten aluminum – ZheLu , The product will supply to all over the world, such as: Muscat, Australia, Paraguay, Foshan Zhelu, a specialized company in aluminum extrusion, perfectly help solve all problems of aluminum plant.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!