ceramic fiber fixed powder to fix launder system

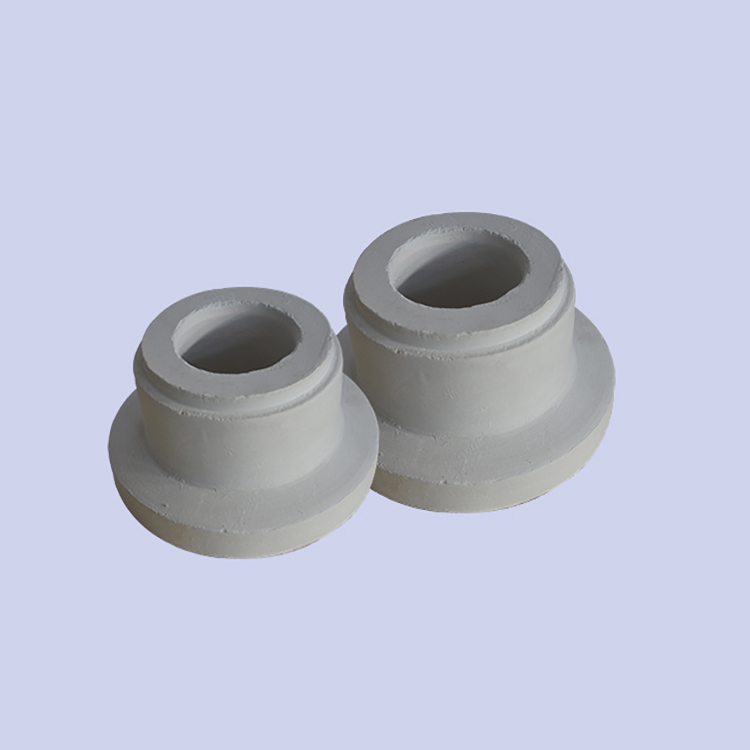

The liquid aluminum vertical flow pipe is made of high-silicon molten material as a whole, with strong corrosion resistance, no pollution to molten metal, and can be used multiple times to meet the production of high value-added, high-tech performance requirements of aviation, transportation and other aluminum alloy precision casting products technology need. High-density, high-strength, high-silica (non-stick aluminum material) high-density and high-strength cast aluminum conduit is a kind of aluminum water flow pipe specially developed for the aluminum metal industry. Its unique structure makes it highly efficient and can be used for Precision machined forming products, the plate has low thermal conductivity, good thermal stability, anti-wetting and corrosion resistance, excellent machinability, and can be used to process some parts of aluminum alloy casting, such as: dropper, flow pipe, hot top ring, Brake pins, ears, floats, continuous casting machine nozzle material, buffer plates, launder memory, machined standpipes and other aluminum industrial products. The synthesis of special high temperature resistant materials determines that the aluminum liquid standpipe has many characteristics that are difficult to replace by other similar materials: high temperature resistance, thermal insulation performance, electrical insulation performance, chemical stability performance, weather resistance performance, etc., especially safety and environmental protection. performance, is the best substitute for other hazardous products. Product advantages: 1. It has the advantages of high strength, erosion resistance, impact resistance, thermal shock resistance, and a smoother surface; 2. It can be used with boron nitride (BN) coatings, and the service life is normal 50-100 casting times; 3. High flexibility in use and operation, enhance the use effect of molten metal transfer equipment, and achieve energy saving and consumption reduction; The advantages of the liquid aluminum vertical flow pipe are that it is easy to disassemble and assemble, and there is no need to stop the equipment during installation. The internal fire-resistant and flame-retardant materials can play the role of sealing and insulating only by bonding the flow pipe from the middle, which does not affect the production of equipment and saves money. installation time. Commonly used in large smelting equipment.