Welcome to our websites!

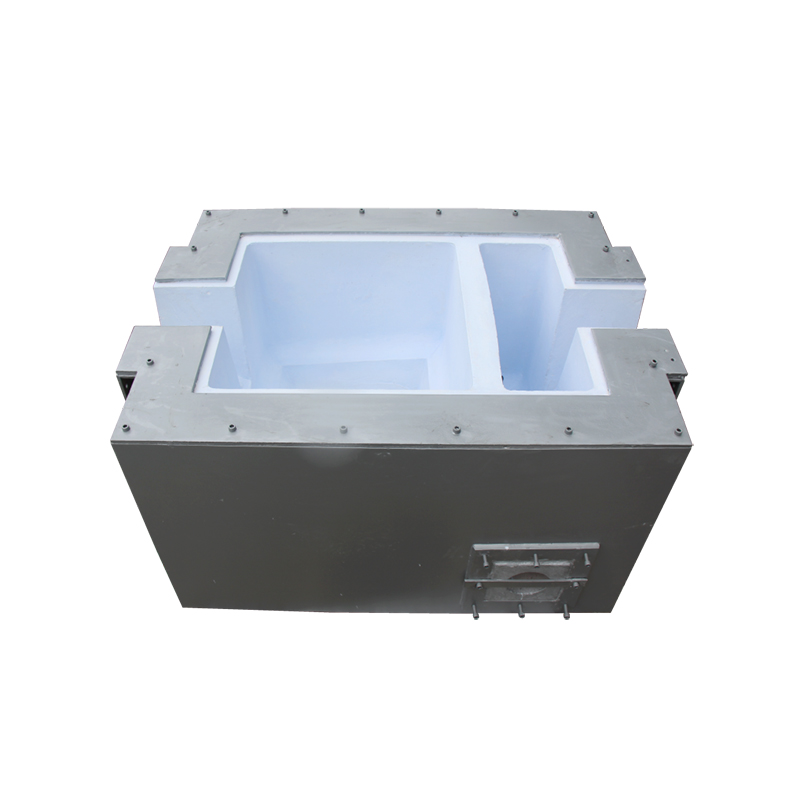

Big discounting Crystallizer - filter box with ceramic filter board filtering molten aluminum – ZheLu

Big discounting Crystallizer - filter box with ceramic filter board filtering molten aluminum – ZheLu Detail:

1. It can be used directly at room temperature without worrying about thermal shock.

2. No thermal expansion and low thermal conductivity.

3. It can float in aluminum, reducing the possibility of refractory inclusions.

Product detail pictures:

Related Product Guide:

Foshan Zhelu has the most advanced aluminum extrusion process in China, as a service company or solution company, we can help any aluminum plant to solve the current problems, or provide the most complete product service, we can give China's most advanced casting and extrusion process. Big discounting Crystallizer - filter box with ceramic filter board filtering molten aluminum – ZheLu , The product will supply to all over the world, such as: Botswana, Munich, Paris, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!