Welcome to our websites!

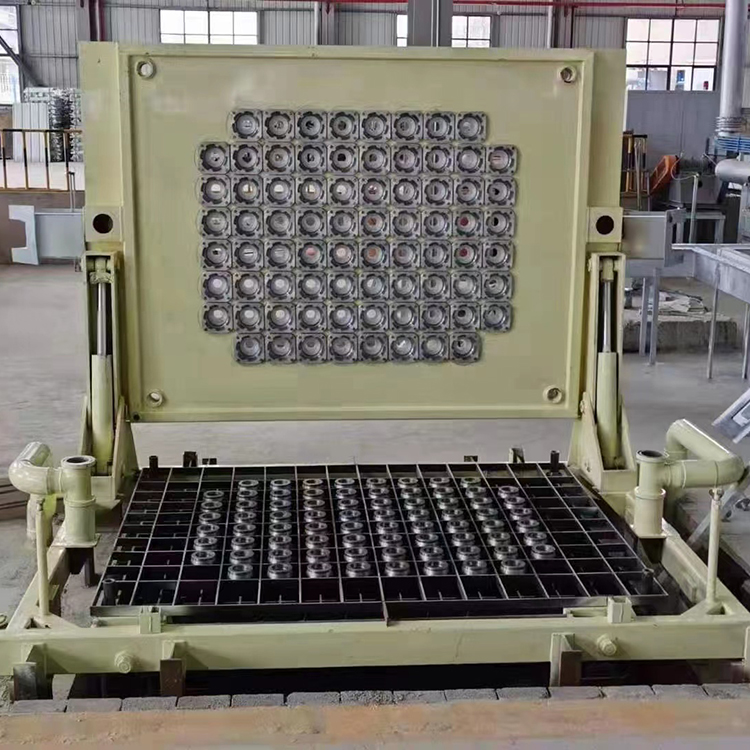

Best-Selling Aluminum Titanium Boron Wire - Water Mist Quenching System For Aluminum Profile Extrusion Machine – ZheLu

Best-Selling Aluminum Titanium Boron Wire - Water Mist Quenching System For Aluminum Profile Extrusion Machine – ZheLu Detail:

5. Human-machine interface control and parameter memory function

Man-machine interface control, all actions and adjustments of the system can be controlled through the man-machine interface, which is easy to operate. Parameter memory function, in order to improve the efficiency of adjustment, the control system has designed a parameter memory function. Each reasonable process parameter system can be memorized, and the next time the same product is produced, the system will call the memorized parameters for production. The system has remote debugging, monitoring and maintenance functions.

Product detail pictures:

Related Product Guide:

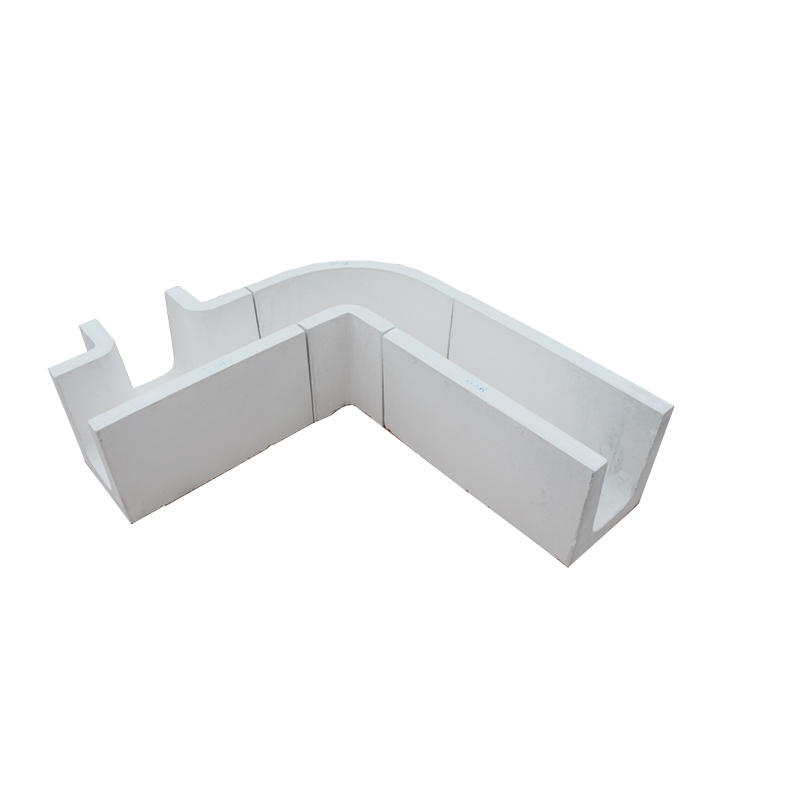

Our products are mainly used in the smelting process of the aluminum casting industry and the extrusion process of aluminum profiles. Best-Selling Aluminum Titanium Boron Wire - Water Mist Quenching System For Aluminum Profile Extrusion Machine – ZheLu , The product will supply to all over the world, such as: Suriname, Brunei, Johor, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!