Aluminum Billet Cutting Machine

Brief description of use:

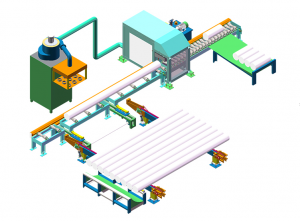

Use a forklift to put the aluminum rods on the conveying chain of the aluminum rod device, the feeder lifts up multiple aluminum rods and moves them to the conveyor belt, and the feed conveyor sends the aluminum rods to the gang saw host for compact sawing the material head, the cut material head automatically falls to the material head and material tail collection box, digitally input the cutting size of the long and short rods, the sawing of the long and short rods is fed and compressed by the manipulator clamping the aluminum rod in a cycle, and the feeding length is counted by the encoder Control, aluminum scraps are automatically collected into briquettes, the sawed long and short rods are moved from the unloading machine to the discharge storage table, and the manipulator or stacker will frame the aluminum rods. The entire production line is controlled by PLC, and the man-machine interface digital input , Automatic chain protection.

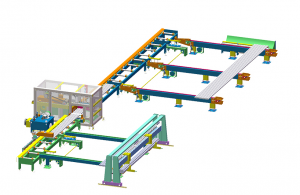

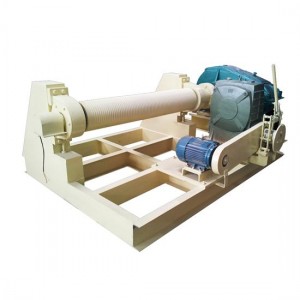

Equipment composition: The long and short rod gang saw production line consists of a five-meter conveyor chain frame, rod counting function, multi-rod loading and unloading machine, feeding conveyor frame, short rod clamping and conveying device, long rod stacking device, automatic weighing, laser coding , short bar gang saw host, aluminum shavings collection briquetting block, discharge storage ingot frame, material head collection frame, hydraulic system, electrical control system, etc.