Welcome to our websites!

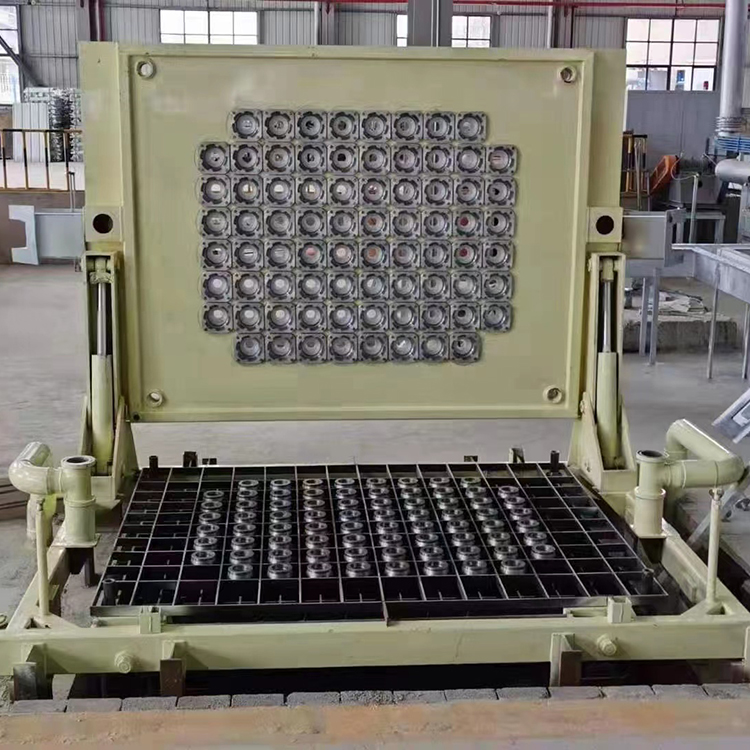

8 Year Exporter Cutting Aluminium Extrusion - Hot top billet Continuous casting machine – ZheLu

8 Year Exporter Cutting Aluminium Extrusion - Hot top billet Continuous casting machine – ZheLu Detail:

Product detail pictures:

Related Product Guide:

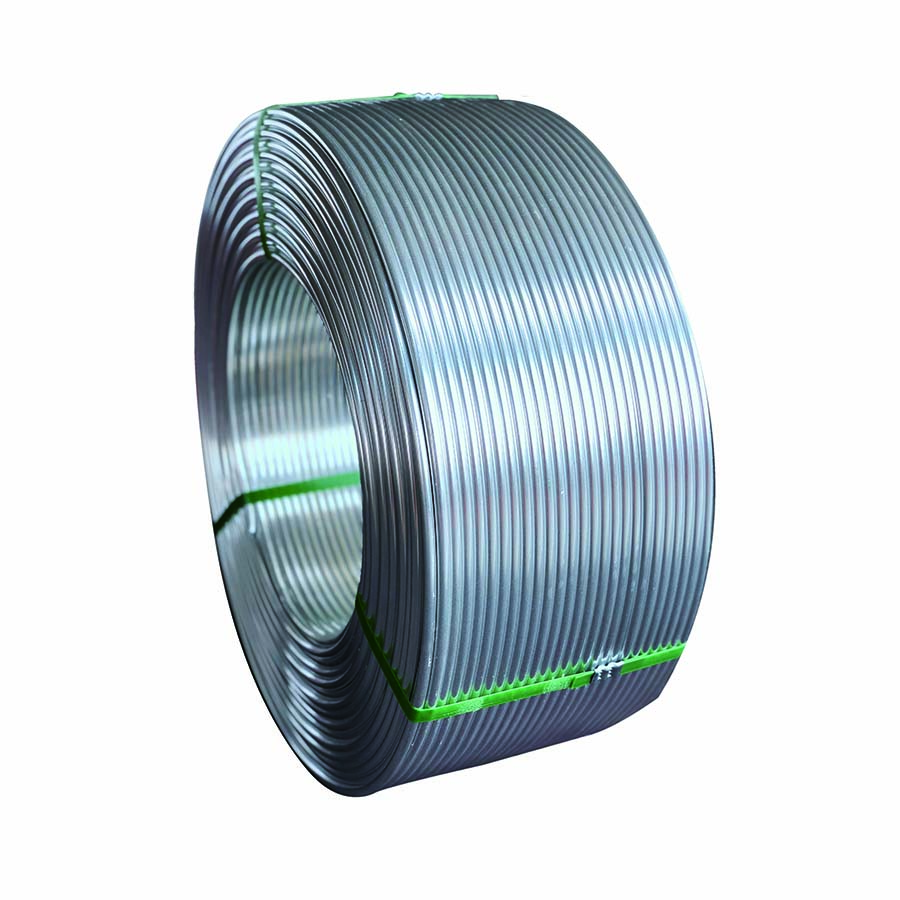

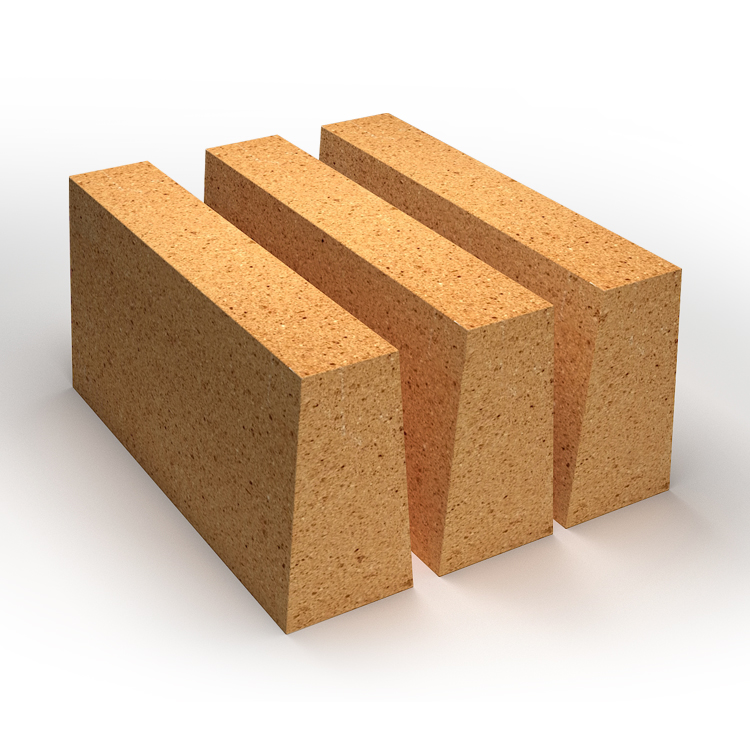

We can fully provide all the materials and accessories used in the production of aluminum ingot production and aluminum rod, including aluminum melting furnace equipment, launder, filter box, online degassing equipment, hot top casting, aluminum ingot casting production line, stacking ingot robot, dust removal equipment, ash stir-frying machine, ball mill, etc., out of the casting industry, the post-processing link of aluminum rod - aluminum profile extrusion, we can also provide products. Aluminum extruder, single rod heating furnace or multi-rod heating furnace, mold heating furnace, mold nitriding furnace, hydraulic oil cooler, cold bed, straightening machine, traction machine, online quenching, aging furnace, air compressor and other equipment, as well as graphite plate, mold, high temperature drum, ring belt, felt sleeve and other consumable materials. 8 Year Exporter Cutting Aluminium Extrusion - Hot top billet Continuous casting machine – ZheLu , The product will supply to all over the world, such as: Somalia, Hongkong, New Zealand, Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.