Welcome to our websites!

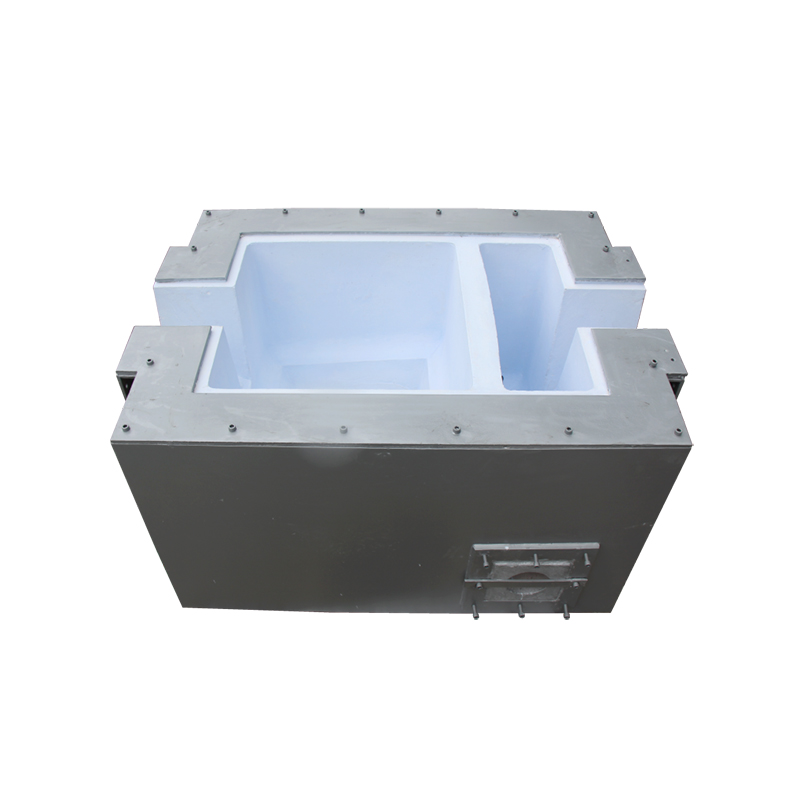

2022 New Style Metal Extruder Machine - filter box with ceramic filter board filtering molten aluminum – ZheLu

2022 New Style Metal Extruder Machine - filter box with ceramic filter board filtering molten aluminum – ZheLu Detail:

1. It can be used directly at room temperature without worrying about thermal shock.

2. No thermal expansion and low thermal conductivity.

3. It can float in aluminum, reducing the possibility of refractory inclusions.

Product detail pictures:

Related Product Guide:

Aluminum extrusion press machine We can supply equipment from 600UST-12000UST tonnage, as well as all rear equipment to match it. 2022 New Style Metal Extruder Machine - filter box with ceramic filter board filtering molten aluminum – ZheLu , The product will supply to all over the world, such as: Seychelles, Finland, azerbaijan, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!