2022 Latest Design Refractory Cast Material - Liquid and solid Low Temperature Polishing Additive including oil degreasing – ZheLu

2022 Latest Design Refractory Cast Material - Liquid and solid Low Temperature Polishing Additive including oil degreasing – ZheLu Detail:

1.To determine the concentration of FL-01 and keep it within the range of operating condition,replenish in time.

2.It is better that the aluminum profiles should be rinsing once before the brightening process for avoiding too much aluminum debris and impurities be taken in, which will influence, degreasing effect and increase the consumption of Low Temperature Polishing Additive.

3.The bath should be cleaned regularly during production because there were some insoluble substances like mechanical sundries and dust.

Low Temperature Polishing Additive is packed with sealed plastic barrel, 30kg net each.

Low temperature polishing sink–assay method

Required reagents: 1N NaOH standard solution ②1% phenolphthalein indicator ③ Potassium

①Accurately pipette 20mL of the bath solution into a 250mL conical flask, add 50mL of distilled water, then add 2 to 3 drops of 1% phenolphthalein indicator, and titrate with 1N NaOH until the solution changes from colorless to pink, which is the end point. Write down V1 without fading within 30s.

②Accurately pipette 5mL of the sink solution into a 250mL conical flask, add 50mL of distilled water, add 3g of potassium fluoride, dissolve and shake well, add 2 to 3 drops of 1% phenolphthalein indicator, and titrate with 1N NaOH until the solution is Colorless to pink is the end point, and V2 is recorded if the color does not fade within 30s .

calculate

work point (number of points) = 9.8 × V 1 × N

Free acid ((g/L)=9.8×V 2 ×N

|

work point |

free acid |

temperature |

|

90~130 |

20~35g/L |

18~25℃ |

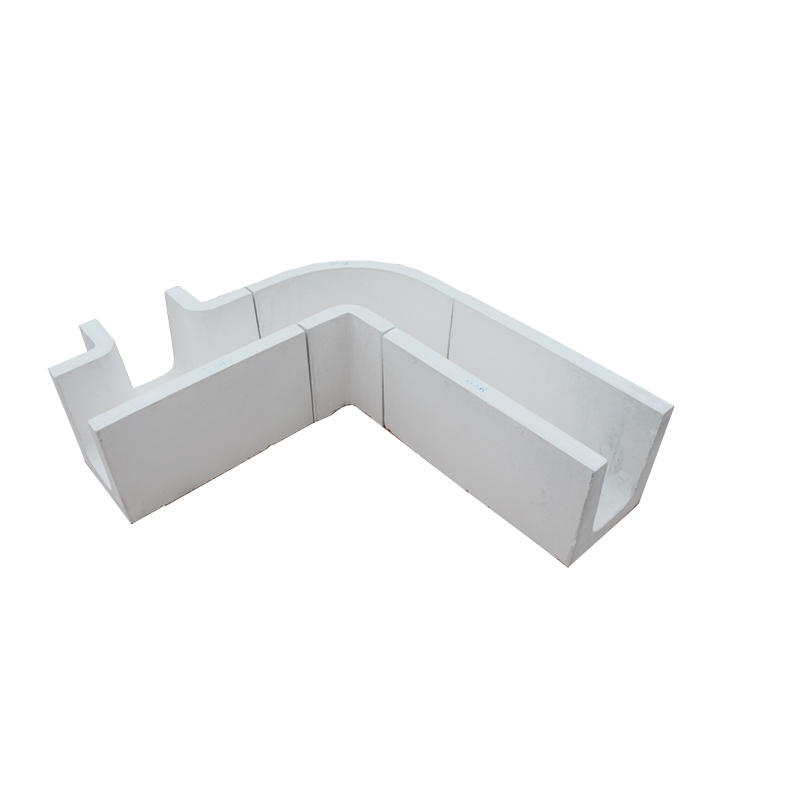

Product detail pictures:

Related Product Guide:

The company has set branches and warehouses in Hanoi and Ho Chi Minh, Vietnam.Yearly we exports there more than 6,000 tons of casting and extrusion consumables ,as well as dozens of casting and extrusion production lines. In the future, we will set up our branch offices in more countries, through face-to-face communication with customers, we will provide door-to-door one-stop service to our customers to solve all the problems. 2022 Latest Design Refractory Cast Material - Liquid and solid Low Temperature Polishing Additive including oil degreasing – ZheLu , The product will supply to all over the world, such as: Azerbaijan, Kuala Lumpur, panama, Foshan Zhelu--solution of aluminum profile anodizing production line

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.